Water Pump Applications and Global Market

From irrigating vast farmlands to circulating water in our homes, the water pump is a fundamental technology that often operates out of sight. This simple yet critical mechanical device, designed to move water from one location to another, is indispensable across nearly every sector of society. The global water pump market is a testament to this importance, with projections indicating it will grow to exceed $77 billion in the coming years. As the world grapples with water management and conservation, understanding the water pump—its core mechanics, diverse forms, and wide-ranging applications—is more relevant than ever.

What Are the Core Working Principles of a Water Pump?

At its heart, a water pump operates by converting mechanical energy into hydraulic energy to move fluid. The many common principle is the creation of a pressure difference. By rapidly altering pressure within a system, a pump can draw water in and force it out. many pumps achieve this through a rotating impeller, which creates a low-pressure area at the inlet to suck water in and a high-pressure area at the outlet to push it out. This is similar to sucking liquid through a straw, where creating a partial vacuum in your mouth allows atmospheric pressure to push the liquid up. A critical physical limit for this suction lift at sea level is approximately 26 feet for centrifugal pumps, a constraint imposed by atmospheric pressure. This fundamental action, whether through a spinning impeller, oscillating diaphragm, or meshing gears, is the universal starting point for all water pump functions.

What Are the Main Functional Categories of Water Pumps?

Water pumps are broadly classified into two main categories based on their method of displacement: centrifugal (or dynamic) pumps and positive displacement pumps. Centrifugal pumps, the many common type, use a rotating impeller to transfer energy to the water, creating velocity that is converted into pressure. They are known for handling high flow rates of relatively clean, low-viscosity fluids like water but must be primed with liquid before starting. In contrast, positive displacement pumps work by mechanically trapping a fixed volume of water and forcing it into the discharge pipe. This design allows them to move highly viscous fluids and provides a consistent flow rate regardless of pressure changes, making them ideal for chemical processing, dosing, and handling thick fluids like oils or sludge. A key safety distinction is that a positive displacement pump must never operate against a closed valve, as it will continue to build pressure until something fails, necessitating a relief valve.

Where Are Water Pumps Primarily Applied in Society?

The applications for water pumps span virtually every domain of human activity. In residential settings, they are crucial for accessing well water, boosting household water pressure, and protecting homes from flooding with sump pumps. Agriculture is heavily dependent on pumps for large-scale irrigation, drainage, and supplying water to livestock. Industrially, they are workhorses in manufacturing for cooling systems, chemical transfer, and wastewater treatment. Municipalities rely on massive pump networks for public water supply, sewage transport, and stormwater management. Specialized applications are equally vital, including marine bilge pumps for boat safety, demand pumps in RVs, and booster pumps for reverse osmosis filtration systems. Furthermore, emergency services deploy high-capacity pumps for firefighting and flood relief, underscoring their role in crisis management.

The water pump is far more than a simple tool; it is a cornerstone of modern infrastructure that enables public health, food security, industrial production, and property safety. Its evolution from ancient devices like the shadoof to today's smart, sensor-equipped and solar-powered models reflects our ongoing relationship with managing water. As technology advances with IoT integration and a focus on energy efficiency, the humble water pump will continue to be an essential force in building a sustainable and resilient future for communities worldwide.

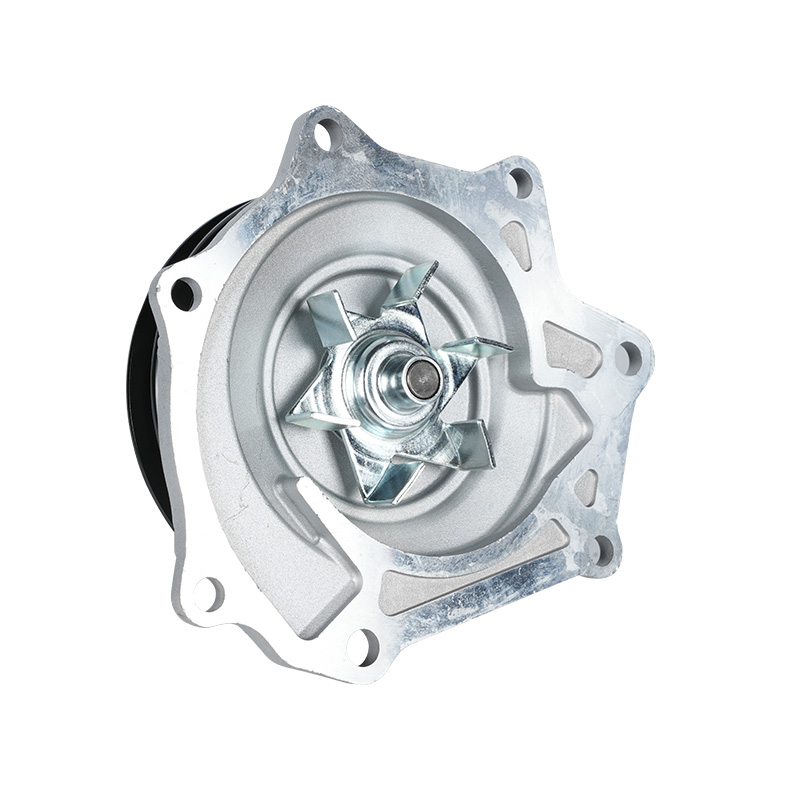

The CZL-F-012 from ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD. is designed for high-capacity and reliable fluid handling in industrial and municipal settings. It features a heavy-duty construction with advanced hydraulic engineering, ensuring stable performance under continuous heavy loads and varying pressure conditions. The pump’s durable materials and efficient motor deliver extended service life with small maintenance, making it suitable for large-scale water supply, drainage systems, and agricultural irrigation. With its powerful output, energy-efficient operation, and adaptability to demanding environments, the CZL-F-012 provides a cost-effective and dependable solution for critical fluid transfer tasks.

English

English 中文简体

中文简体