Forklift Pump Selection Guides Operational Efficiency

In the bustling environment of warehouses, ports, and manufacturing facilities, the forklift pump operates as the critical circulatory system of the material handling equipment. Selecting the correct forklift pump is not merely a maintenance task but a strategic decision impacting operational efficiency, safety, and total cost of ownership. This choice hinges on understanding the distinct types, their operational principles, and the maintenance philosophies required to ensure longevity and reliability.

What Are the Main Types of Forklift Pumps?

The term "forklift pump" primarily encompasses two vital systems: the hydraulic pump and the engine coolant pump. For the hydraulic system, which provides the lifting and tilting force, the main types are gear pumps, vane pumps, and piston pumps. Gear pumps, known for their durability and cost-effectiveness in handling standard hydraulic fluids, are commonly found in many standard-duty forklifts. Vane pumps offer smoother operation and are often selected for applications requiring consistent performance. Piston pumps, capable of higher pressures, are typically reserved for high-intensity, heavy-duty cycling. The selection process must carefully balance required system pressure, which can range from 1500 to over 3000 PSI in demanding applications, desired flow rates for operational speed, energy efficiency goals, and budget constraints. Matching the pump to the forklift's specific duty cycle is paramount to avoiding premature wear or inadequate performance.

How Does a Forklift Pump Actually Work?

The core working principle of a forklift hydraulic pump is the conversion of mechanical energy into hydraulic energy. Driven directly by the forklift's engine or electric motor, the pump's internal mechanism—be it gears, vanes, or pistons—creates a vacuum at its inlet, drawing hydraulic fluid from the reservoir. This fluid is then mechanically trapped, pressurized, and forcibly discharged into the hydraulic system. This pressurized oil travels through valves and hoses to actuators like lift cylinders, creating the immense force needed to raise multi-ton loads. The efficiency of this energy transfer is a key performance metric, with modern designs focusing on minimizing internal leakage and mechanical losses. The entire system operates on a closed loop, with fluid returning to the reservoir after performing its work, ready to be pressurized again.

How Should They Be Maintained?

Regular maintenance is the many effective strategy for preventing common forklift pump failures. Issues often manifest as slow operation, a loss of lifting power, or unusual noises, which can indicate problems like pump wear, internal leakage, or cavitation—a damaging condition where vapor bubbles form and collapse in the fluid. Contamination from particulates or water is a pilot cause of pump wear and valve malfunctions. Therefore, a rigorous maintenance regimen centered on fluid management is essential. This includes scheduled changes of the hydraulic fluid and filters; industry data suggests that a significant proportion of hydraulic system failures can be traced to fluid contamination. Regular visual inspections for leaks, monitoring fluid temperature, and listening for changes in pump sound are crucial diagnostic practices. Proactive maintenance not only prevents costly unplanned downtime but also extends the service life of the pump, protecting the substantial investment in the material handling equipment.

Informed selection and diligent care of the forklift pump are fundamental to sustainable operations. By understanding the technical nuances between pump types, respecting their operational principles, and committing to a proactive maintenance culture focused on fluid integrity, businesses can ensure their forklifts remain reliable and productive assets. This approach directly supports smoother logistics, enhanced safety, and better control over long-term operational costs in the demanding world of material handling.

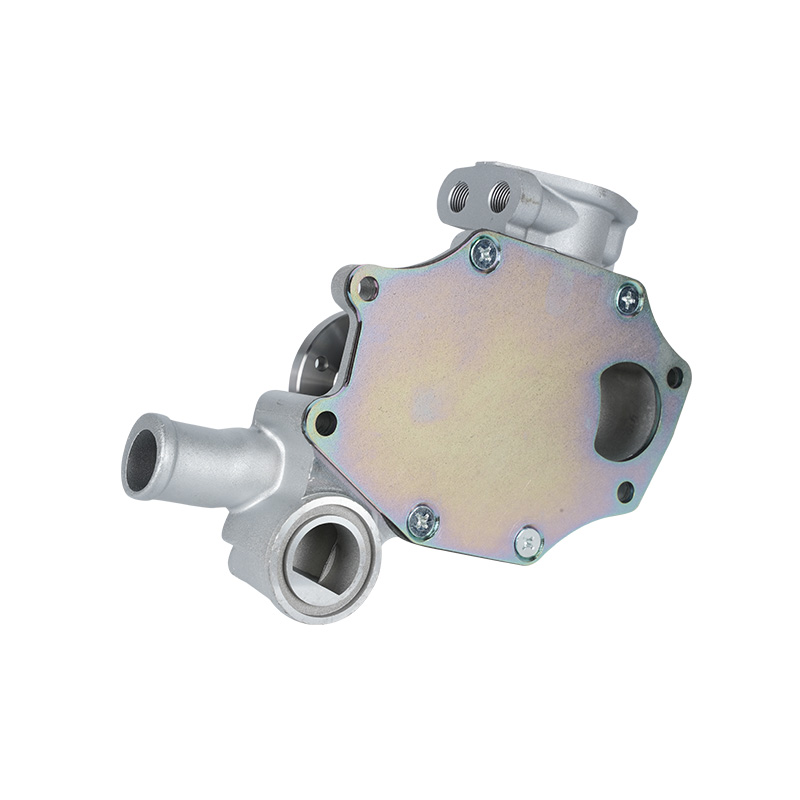

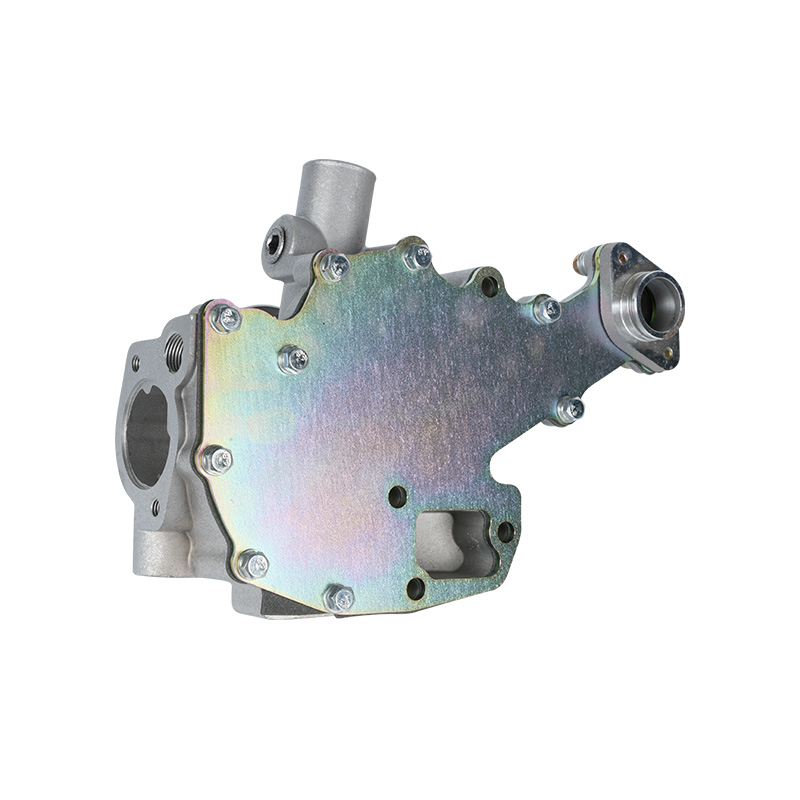

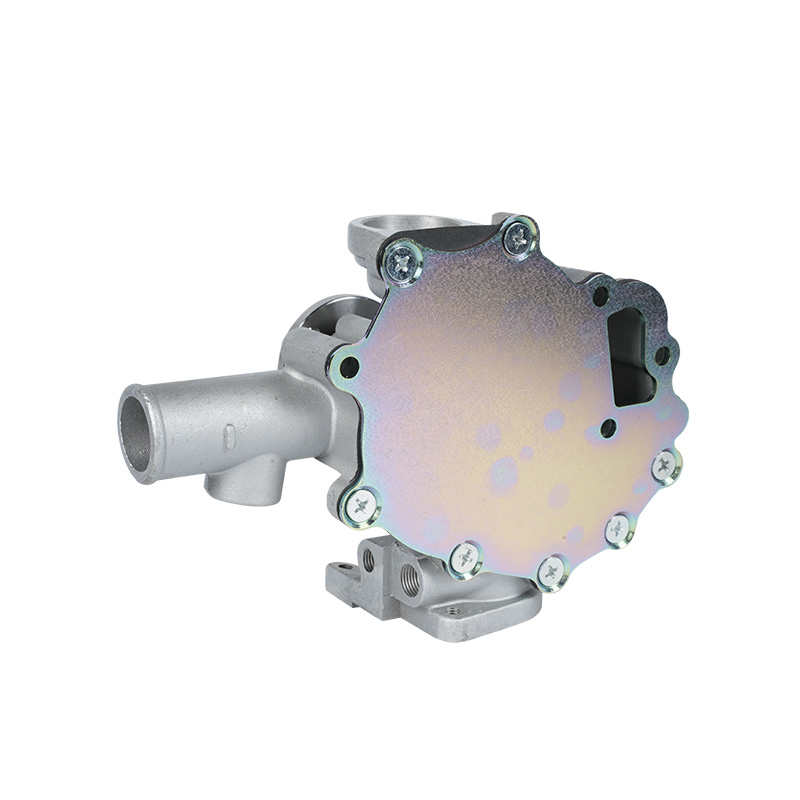

For industrial applications requiring durable and efficient fluid transfer, the CZL-F-004 pump from ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD. stands as a robust and reliable solution. Engineered with an optimized hydraulic design and wear-resistant construction, this pump delivers consistent performance in demanding environments such as chemical processing, industrial water circulation, and wastewater management. Its compact structure allows for easy installation and maintenance, while key components can be configured with enhanced materials to handle corrosive or particle-laden media. Recommended for operations that prioritize long-term operational stability, energy efficiency, and adaptability, the CZL-F-004 offers a cost-effective balance of performance and durability for continuous industrial use.

English

English 中文简体

中文简体