Forklift Water Pump Guide Key Maintenance Tips

In the demanding world of material handling and warehouse logistics, the reliability of equipment is paramount. Among the many components ensuring smooth operation, the Forklift Water Pump plays an indispensable, yet often overlooked, role. This essential part of an internal combustion forklift's cooling system is central to preventing engine overheating and maintaining operational efficiency. With forklifts often operating in multi-shift environments, understanding the Forklift Water Pump—its function, market options, and maintenance needs—is key to reducing unplanned downtime and managing fleet costs effectively.

How Does a Forklift Water Pump Work and What is Its Structure?

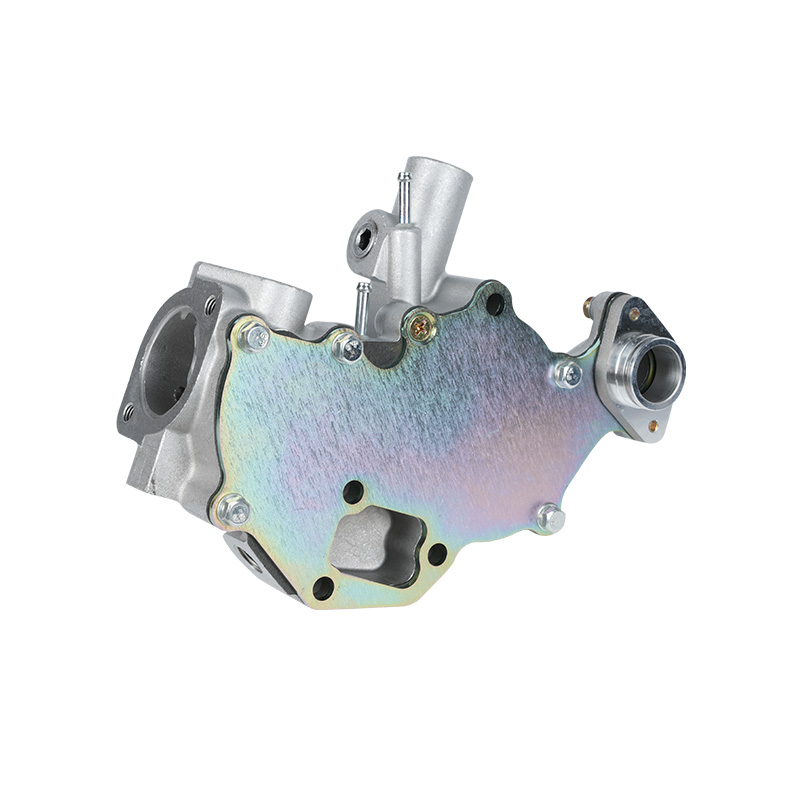

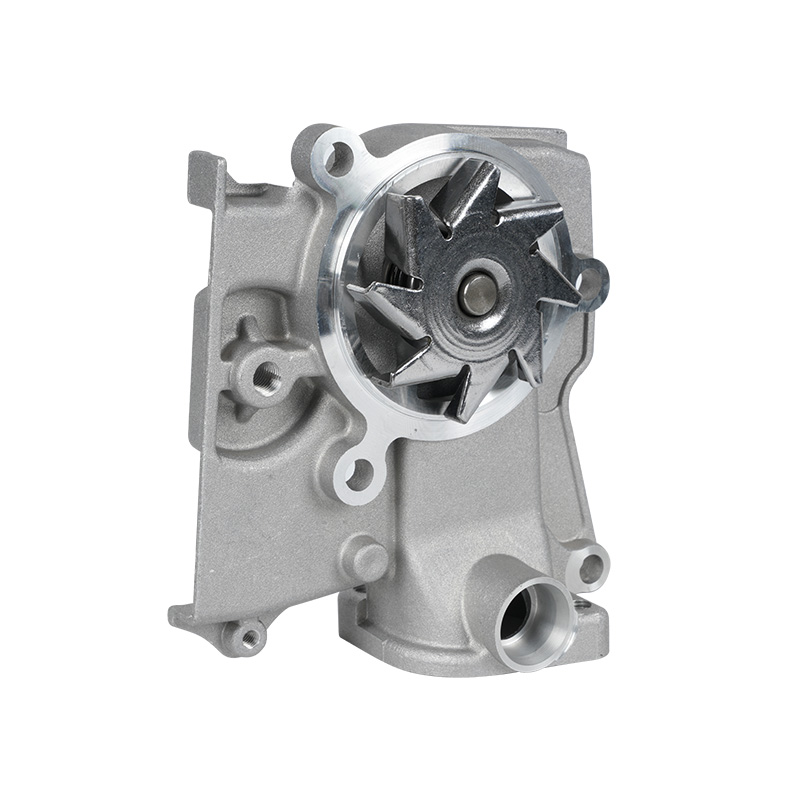

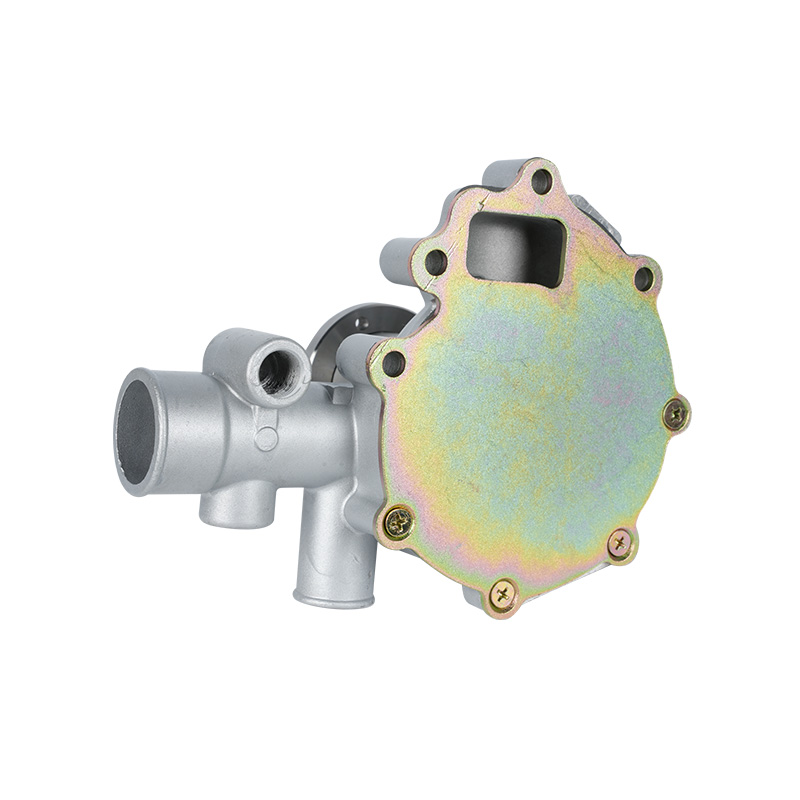

The primary function of a Forklift Water Pump is to circulate engine coolant continuously. It operates as a centrifugal pump, typically driven by a belt connected to the engine's crankshaft. As the engine runs, this rotation spins the pump's impeller, creating a flow that draws cooled liquid from the radiator and pushes it through the engine block and cylinder head. This process absorbs excess combustion heat before returning the warmed coolant to the radiator to be cooled again. The Forklift Water Pump is engineered for durability, with a housing commonly made from cast aluminum or iron to withstand pressure and thermal stress. The impeller, the component that moves the fluid, is often constructed from stamped steel, durable composites, or bronze, materials chosen for their resistance to corrosion from coolant mixtures. A critical seal and bearing assembly allows the shaft to spin smoothly while preventing coolant leaks, making the design and quality of these internal parts vital for the Forklift Water Pump's service life.

What Are the Purchase and Market Selection Options?

When a Forklift Water Pump fails, operators are typically presented with a choice between new and remanufactured units. The market for these components is segmented accordingly, serving the diverse needs of large fleets and individual owners. A new Forklift Water Pump offers the reassurance of unused components and often comes with a standard manufacturer's warranty, providing predictable performance. In contrast, a professionally remanufactured Forklift Water Pump—where the core unit is disassembled, cleaned, fitted with new seals, bearings, and sometimes impellers, and rigorously tested—can offer substantial cost savings, sometimes priced significantly lower than a new unit. These remanufactured parts frequently carry warranties of 90 days or more, providing a balance of economy and reliability. The selection often depends on the forklift's residual value and intended service life, with remanufactured parts being a common and practical choice for maintaining older models or managing large-scale maintenance budgets.

What Are the Common Failure Points and Maintenance Essentials?

Proactive attention can extend the service interval of a Forklift Water Pump. One of the pilot causes of premature failure is improper belt tension. A belt that is too tight places excessive side load on the pump's bearing, pilot to early wear and seal damage. Conversely, a loose belt can cause slippage and inadequate coolant flow, resulting in engine overheating. Regular visual inspections are crucial; technicians look for signs of coolant leakage from the pump's weep hole, which indicates a failing seal. Coolant quality is another critical factor. Using the correct type of coolant and changing it at recommended intervals prevents corrosion and scale buildup that can degrade the impeller and internal passages. These maintenance practices are not just about the pump itself but about sustaining the entire thermal management system.

The Forklift Water Pump is a small component with a major impact on operational continuity. Its role in managing engine temperature is non-negotiable for safe and efficient forklift operation. By understanding its centrifugal pumping action, making informed choices between new and remanufactured market options, and adhering to maintenance fundamentals focused on belt tension and coolant management, fleet managers can optimize performance and avoid costly breakdowns. As warehouse operations intensify, the disciplined care of foundational components like the Forklift Water Pump will remain a cornerstone of reliable material handling.

The CZL-F-008 from ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD. is engineered for efficient and stable fluid transfer in demanding applications. This pump features a robust design with advanced hydraulic components that ensure consistent performance under high-pressure and continuous operation conditions. Its high-quality materials and precision engineering provide exceptional durability, small maintenance requirements, and reliable operation in industrial, agricultural, and municipal water systems. Compact in structure yet powerful in output, the CZL-F-008 is an ideal solution for applications requiring dependable long-term performance, offering both cost-effectiveness and operational efficiency in challenging environments.

English

English 中文简体

中文简体