Excavator Pump Selection Influences Machine Performance

In the demanding world of construction and earthmoving, the excavator pump stands as the indispensable heart of the hydraulic system. This critical component is responsible for converting engine power into the hydraulic force that drives every movement of the machine, from the precise curl of the bucket to the powerful swing of the upper structure. Selecting the correct excavator pump is therefore not a routine replacement task but a crucial decision that directly impacts machine productivity, fuel efficiency, and long-term operating costs. A thorough understanding of its operation, specifications, and potential failure modes is essential for making an informed investment.

How Does an Excavator Pump Work?

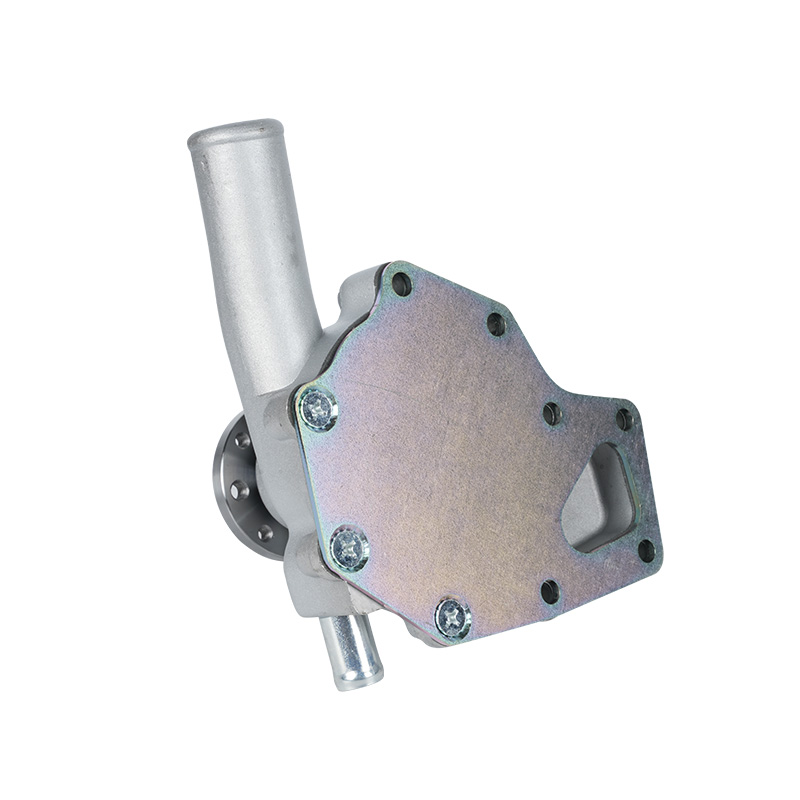

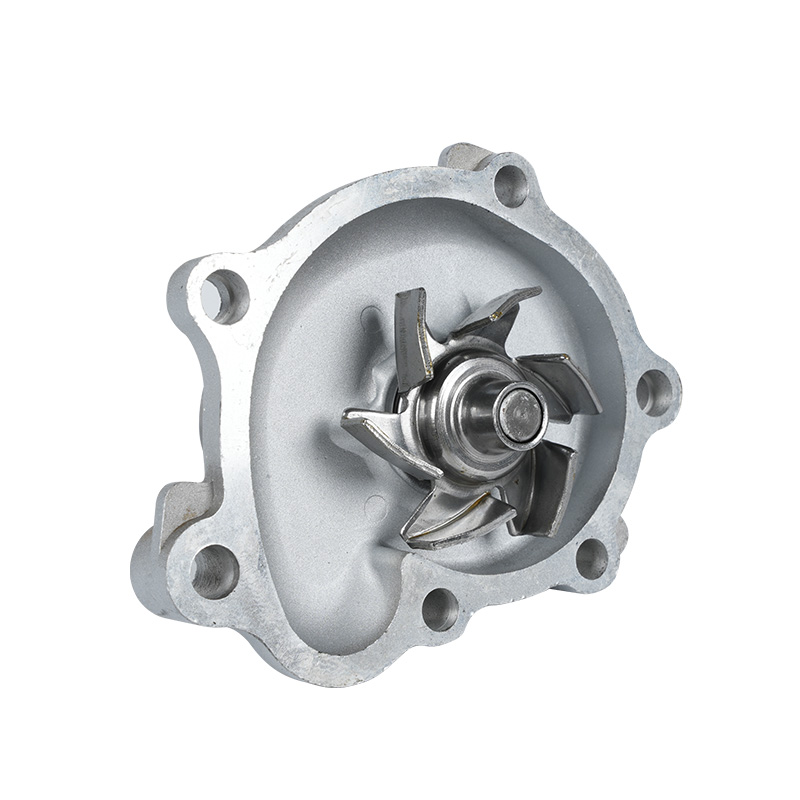

The fundamental working principle of an excavator pump, many commonly an axial piston pump in modern machines, revolves around the efficient conversion of mechanical rotation into hydraulic flow. Driven by the excavator's engine, the pump's rotating swashplate or cylinder block causes a series of pistons to reciprocate within their bores. This action draws hydraulic fluid from the reservoir during the intake stroke and then pressurizes it during the discharge stroke. The angle of the swashplate dictates the displacement of the pump, thereby controlling the volume of high-pressure oil delivered to the system. This pressurized fluid is then directed through control valves to the various hydraulic actuators—the cylinders and motors—enabling the powerful and controlled movements essential for excavation work.

What Are the Key Performance Parameters for Selection?

Several key performance parameters must be carefully evaluated during the selection of an excavator pump to ensure compatibility and ideal performance. The many critical are pressure rating, flow rate, and displacement. Operating pressure, typically measured in bar or psi, defines the force the hydraulic system can generate; modern excavator pumps often operate reliably in ranges from 300 to 400 bar. Flow rate, measured in liters per minute or gallons per minute, determines the speed of the hydraulic functions; a pump for a mid-sized 20-ton excavator may need to deliver a flow exceeding 150 liters per minute. Displacement, measured in cubic centimeters per revolution, indicates the pump's size and its oil output per engine revolution. Matching these parameters precisely to the original equipment specifications or the specific demands of a customized application is paramount to avoid inefficiency, poor performance, or potential system damage.

What Are the Common Failures to Watch For?

Despite their robust design, excavator pumps are susceptible to several common failures, often stemming from contamination, wear, or improper operation. A pilot cause of premature failure is contamination of the hydraulic fluid by microscopic particles, which can score internal surfaces and accelerate wear, pilot to a loss of pressure and efficiency. Cavitation, the formation and collapse of air bubbles within the pump due to restricted inlet flow or using the wrong fluid viscosity, can cause significant damage to metal components and produce a distinct whining noise. Internal leakage past worn pistons, seals, or valve plates results in decreased overall efficiency, slower cycle times, and increased heat generation. External leaks, often from shaft seals or housing gaskets, not only create a mess but also allow contaminant ingress. Recognizing early signs like unusual noises, rising fluid temperatures, or gradually slowing operation can help diagnose these issues before they lead to a complete and costly pump failure, underscoring the importance of proactive maintenance and fluid management.

The process of selecting an excavator pump demands a technical and informed approach. By understanding the precision of its working principle, rigorously matching its key performance parameters to the machine's needs, and being aware of the common failures that can compromise its function, equipment managers and owners can make choices that ensure reliability, improve uptime, and protect their valuable asset. This careful consideration supports not only the immediate task at hand but also the long-term productivity and return on investment of the entire excavation operation.

The CXL-E-008 from ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD. is a multi-stage centrifugal pump engineered for applications requiring high pressure and stable flow. Its compact, vertically segmented design integrates multiple impellers in series, enabling it to generate significant head for tasks such as boiler feed, industrial water supply, high-rise building pressurization, and reverse osmosis system support. Constructed with durable materials like stainless steel for critical components, it ensures reliable performance, low maintenance, and efficient operation in continuous-duty settings where consistent pressure is essential.

English

English 中文简体

中文简体