Excavator Pump Advanced Performance Features

The excavator pump sector continues to demonstrate significant engineering progress, with particular focus on enhancing operational reliability in challenging working environments. These specialized hydraulic components have evolved to address the demanding requirements of modern construction and mining applications. The technological development of the excavator pump reflects the industry's ongoing commitment to improving equipment performance while reducing maintenance demands. The current generation of excavator pump systems incorporates multiple design innovations that collectively contribute to extended service life and consistent operation under difficult conditions.

How Is Clog Prevention Achieved in Excavator Pump Design?

The operational efficiency of modern excavator pump systems heavily depends on effective clog prevention mechanisms. Contemporary excavator pump designs incorporate specialized flow paths and component geometries that less potential accumulation points for debris and fibrous materials. The internal configuration of an advanced excavator pump typically features optimized passages that facilitate smooth movement of mixed solid-liquid materials. These design considerations in the excavator pump significantly reduce the likelihood of operational interruptions caused by blockages. The development of these anti-clogging features in the excavator pump demonstrates the industry's focus on maintaining consistent performance in challenging excavation environments.

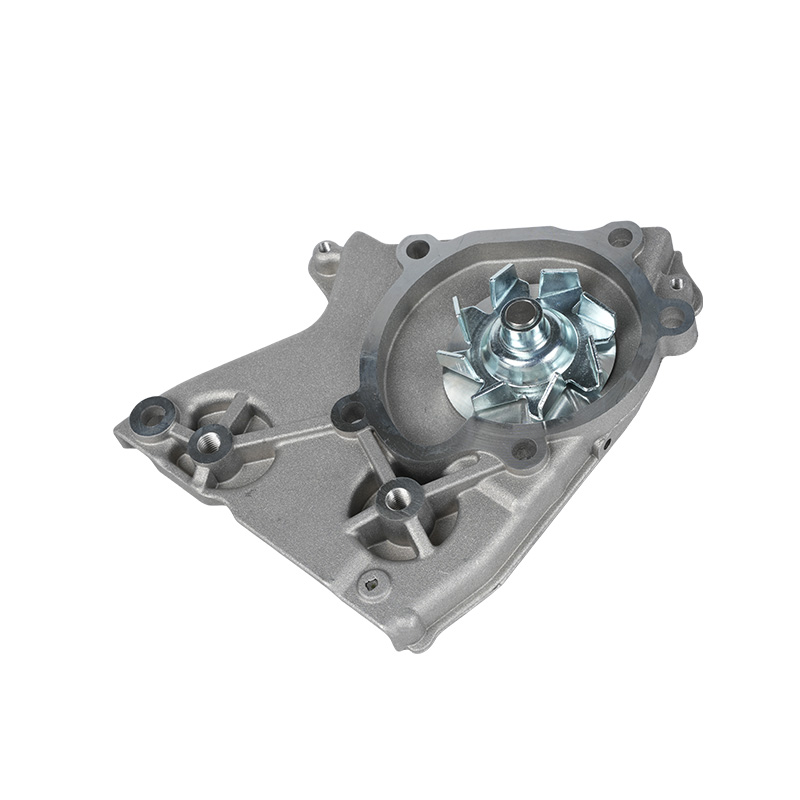

What Makes an Excavator Pump Capable of Handling Solid Materials?

The capacity to process solid materials represents another crucial aspect of excavator pump performance. Modern excavator pump units are engineered to handle various solid contents commonly encountered in excavation and dredging applications. The structural design of a heavy-duty excavator pump typically includes reinforced components and specialized impeller configurations that manage solid particles effectively. These engineering solutions in the excavator pump ensure reliable performance when processing materials with significant solid content. The continuing development of solid handling capabilities in the excavator pump highlights the importance of this characteristic for equipment operating in demanding industrial applications.

Why Is Wear Resistance Crucial in Excavator Pump Construction?

The durability and service life of an excavator pump are substantially influenced by its wear resistance properties. Manufacturers employ specially formulated materials and surface treatments in excavator pump construction to withstand abrasive conditions. The selection of appropriate materials for excavator pump components ensures sustained performance when exposed to various abrasive elements present in excavation environments. These material considerations in excavator pump production contribute directly to the equipment's ability to maintain operational efficiency over extended periods. The ongoing development of wear-resistant solutions for excavator pump applications underscores the critical role of material science in heavy equipment technology.

The continuous technical refinement of excavator pump systems indicates a persistent industry focus on enhancing equipment capabilities through targeted engineering solutions. The integration of clog-resistant designs, robust solid handling features, and advanced wear protection in excavator pump products demonstrates a comprehensive approach to performance optimization. As excavation requirements continue to evolve across different sectors, the development of excavator pump technology remains aligned with practical operational needs and maintenance considerations. These progressive improvements in excavator pump design contribute to more reliable and efficient equipment performance in various challenging applications.

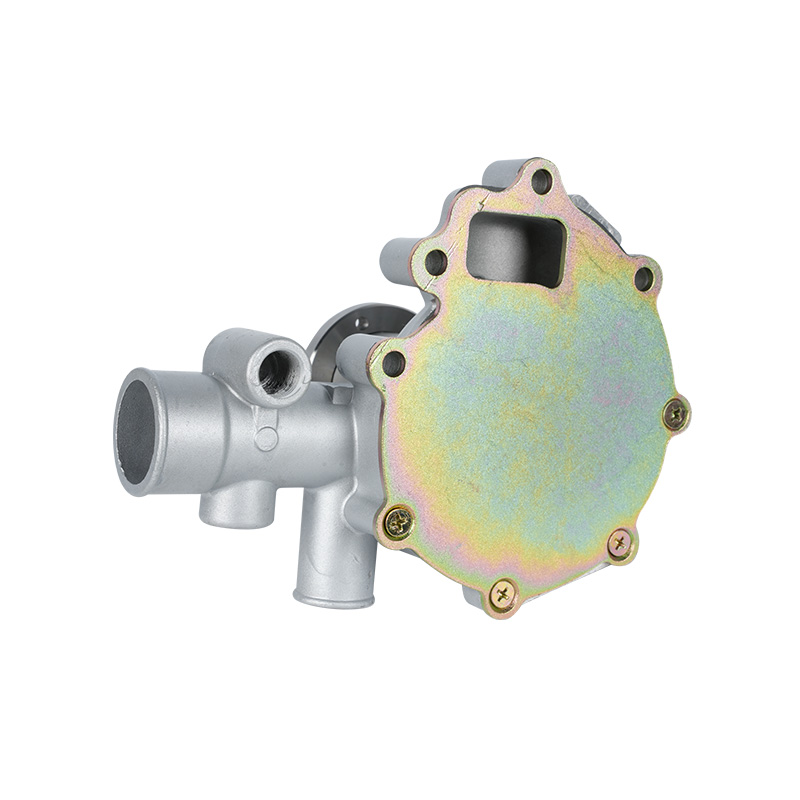

Zhejiang Jinrui Pump Industry Co., Ltd. presents the CXL-E-001 industrial pump, engineered for reliable performance in various fluid handling applications. This robust pump model features a durable construction with optimized hydraulic design, ensuring efficient operation across different industrial environments. The CXL-E-001 incorporates advanced engineering solutions that address common challenges in fluid transfer systems, offering consistent performance while maintaining energy efficiency.

English

English 中文简体

中文简体