Forklift Pump: Technology, Performance, And Future

The Forklift Pump remains a critical component in material handling equipment, with ongoing technological developments enhancing its performance and reliability. As the heart of the hydraulic system in forklifts, this essential component directly influences operational efficiency across various industrial settings. Recent engineering improvements in Forklift Pump design have focused on optimizing energy consumption while maintaining robust performance under demanding working conditions. The evolution of Forklift Pump technology continues to address the growing needs for greater efficiency and reduced environmental impact within the logistics and warehousing sectors.

What Are the Fundamental Technical Principles of Forklift Pump?

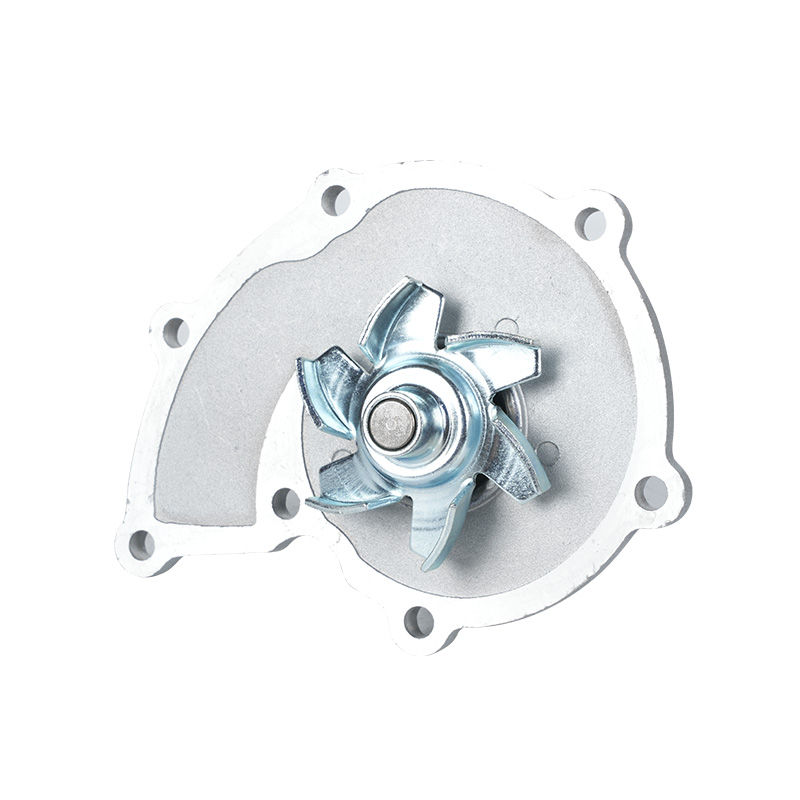

The operational foundation of the Forklift Pump centers on converting mechanical energy into hydraulic power through precise engineering mechanisms. These systems typically utilize either gear-based or piston-driven configurations to generate the necessary fluid pressure for lifting and steering functions. The fundamental working principle involves creating a vacuum that draws hydraulic fluid into the pump chamber, then mechanically forcing it outward under substantial pressure through the discharge port. This process enables the transmission of power to various hydraulic components within the forklift system. The design integrity of the Forklift Pump ensures consistent fluid displacement and pressure maintenance, which are crucial for stable lifting operations and precise load handling.

How Do Different Forklift Pump Configurations Compare in Performance?

When evaluating different Forklift Pump configurations, several performance characteristics emerge as significant differentiators. Variations in design philosophy result in distinct operational attributes including efficiency metrics, pressure capabilities, and service life expectations. Certain pump models demonstrate advantages in specific applications, with selection criteria often depending on particular operational requirements and environmental conditions. The operational efficiency of a Forklift Pump significantly influences overall energy consumption patterns in warehouse operations, making appropriate selection a crucial consideration for cost management. Additionally, the acoustic performance and thermal management capabilities vary substantially between different Forklift Pump technologies, affecting both operator comfort and maintenance scheduling.

What Future Trends Are Shaping Forklift Pump Development?

The future development trajectory of Forklift Pump technology points toward enhanced integration with digital monitoring systems and improved energy management capabilities. Emerging designs are increasingly incorporating smart technologies that enable real-time performance tracking and predictive maintenance functions. The evolution of Forklift Pump systems also shows a clear trend toward materials science innovations that reduce internal friction and improve overall efficiency. Another significant direction involves adapting Forklift Pump technology to work with alternative energy systems, reflecting broader industry shifts toward sustainable operations. These advancements in Forklift Pump design are expected to contribute to quieter operation, reduced energy requirements, and extended service intervals. The continuing innovation in Forklift Pump technology demonstrates the industry's commitment to meeting evolving operational demands while addressing environmental considerations through engineering excellence.

The progressive refinement of Forklift Pump technology underscores its vital role in advancing material handling efficiency. As research and development continues, the Forklift Pump is poised to incorporate more sophisticated features that will further optimize performance and reliability. The enduring importance of the Forklift Pump within industrial equipment ensures that technological improvements in this component will remain a priority for manufacturers and operators alike. The ongoing evolution of Forklift Pump systems represents a continuous effort to balance performance demands with operational economy and environmental responsibility.

Product Recommendation

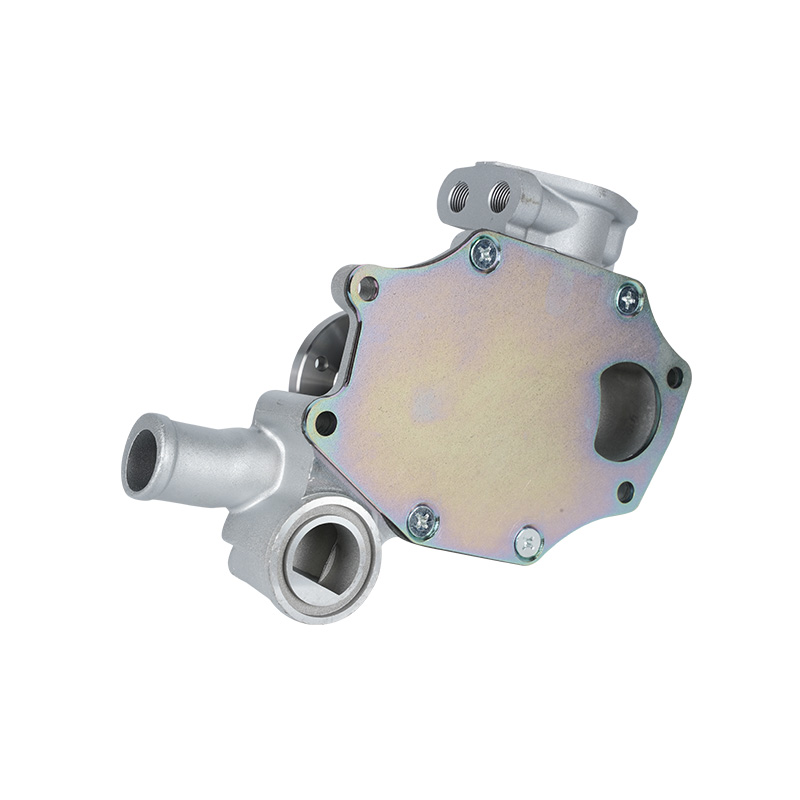

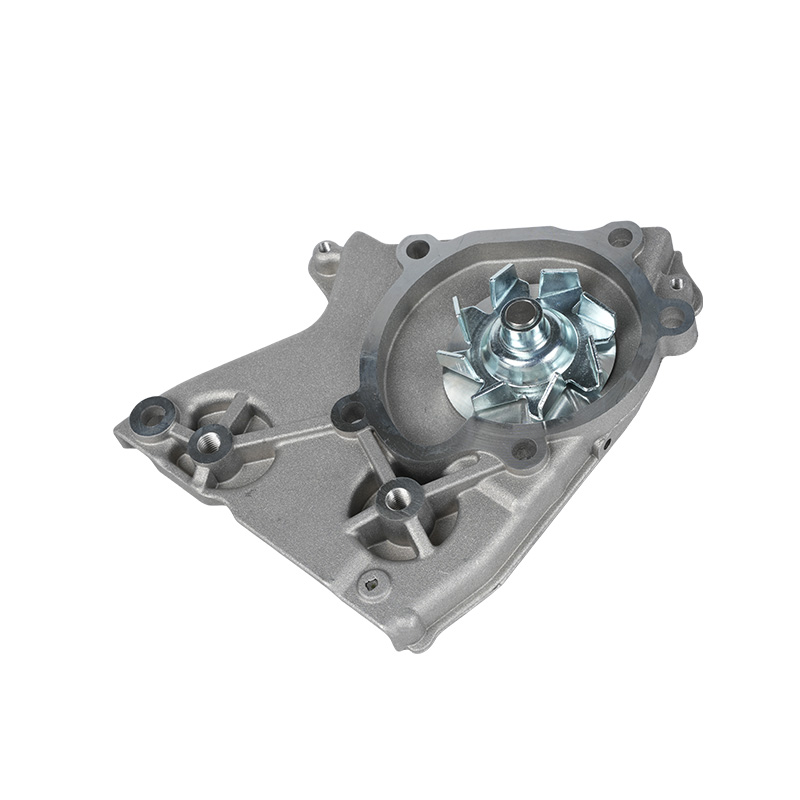

ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD. manufactures the CZL-F-001, a robust and efficient pump model designed for reliable performance in demanding fluid transfer applications. It is engineered with a focus on durability and consistent output, making it a suitable choice for various industrial and commercial scenarios.

English

English 中文简体

中文简体