Engine Water Pump System Fundamentals

The engine water pump remains a fundamental component in automotive cooling systems, with its performance directly influencing engine operational stability. These crucial automotive parts have maintained their importance through decades of internal combustion engine development. The evolution of the engine water pump reflects continuous engineering refinements aimed at enhancing reliability and service life. Modern engine water pump designs incorporate numerous improvements that address common failure modes while maintaining the core functionality that vehicle engines require for proper thermal management.

What Is the Core Operational Role of an Engine Water Pump?

The primary function of any engine water pump centers on maintaining consistent coolant circulation throughout the engine's cooling passages. This continuous movement of coolant enables effective heat transfer from engine components to the radiator system. The operational principle of the engine water pump involves creating sufficient fluid pressure to overcome system resistance while ensuring adequate flow volume. The performance characteristics of the engine water pump must align with specific engine requirements to prevent overheating situations during various operating conditions. This fundamental operation of the engine water pump establishes its critical position in overall vehicle functionality and reliability.

What Are the Essential Components in an Engine Water Pump?

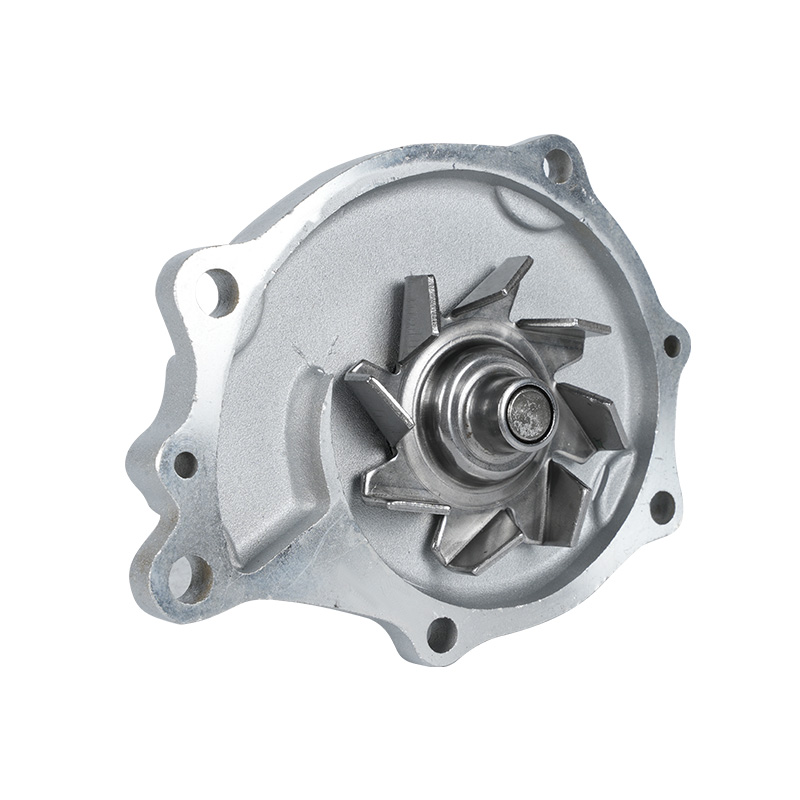

The construction of a typical engine water pump involves several key elements that work together to achieve proper coolant circulation. The impeller represents the central moving part within the engine water pump assembly, responsible for creating the necessary fluid motion. The bearing and shaft system provides the structural support that enables impeller rotation while withstanding operational stresses. Sealing elements within the engine water pump prevent coolant leakage while protecting internal components from contamination. The drive mechanism connects the engine water pump to engine operation, typically utilizing pulley systems that transfer rotational energy from the engine. These combined elements within the engine water pump work in coordination to fulfill its cooling system responsibilities.

What Maintenance Considerations Are Important for an Engine Water Pump?

Proper maintenance practices significantly influence the service life and reliability of any engine water pump. Regular inspection of the cooling system helps identify potential issues before they develop into major problems. Coolant replacement according to manufacturer recommendations preserves the proper chemical environment for engine water pump operation. Monitoring for early warning signs including unusual noises or minor leaks can indicate developing issues within the engine water pump assembly. Addressing these minor concerns promptly often prevents more extensive damage to the engine water pump and associated cooling system components. These maintenance approaches contribute to extended engine water pump longevity and consistent performance.

The continuing importance of the engine water pump in automotive applications ensures ongoing development of improved designs and materials. The fundamental role of the engine water pump in engine temperature regulation maintains its position as an essential vehicle system component. Through proper understanding of its functions, components, and maintenance requirements, vehicle owners can ensure their engine water pump provides reliable service throughout its expected lifespan. The technological evolution of the engine water pump continues to address reliability concerns while adapting to changing engine design requirements across the automotive industry.

Zhejiang Jinrui Pump Industry Co., Ltd. presents the CZL-F-002, a robust industrial pump engineered for demanding fluid handling applications. This pump model combines durable construction with efficient hydraulic design, delivering reliable performance across various industrial environments. The CZL-F-002 features optimized internal components and advanced sealing technology, ensuring consistent operation while small maintenance requirements. Suitable for multiple fluid transfer scenarios, this pump demonstrates the company's commitment to quality and performance in industrial pumping solutions.

English

English 中文简体

中文简体