Yanmar Pump Technology Powers Diverse Industries

In the world of industrial machinery and fluid power, the name Yanmar Pump represents a diverse range of critical components and systems that keep essential equipment operating. Far from a single product, the Yanmar Pump portfolio encompasses specialized solutions for water movement, hydraulic power, and marine propulsion. These technologies serve as the lifeblood for sectors as varied as agriculture, construction, and maritime transport, demonstrating the brand's engineering reach into multiple facets of modern infrastructure.

What Are the Main Classifications of Yanmar Pumps?

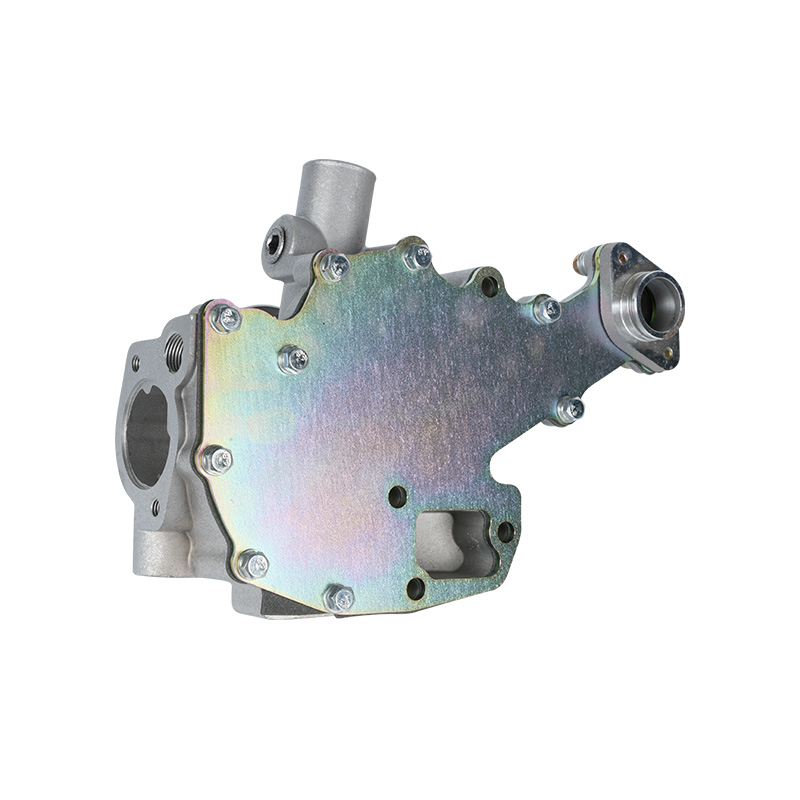

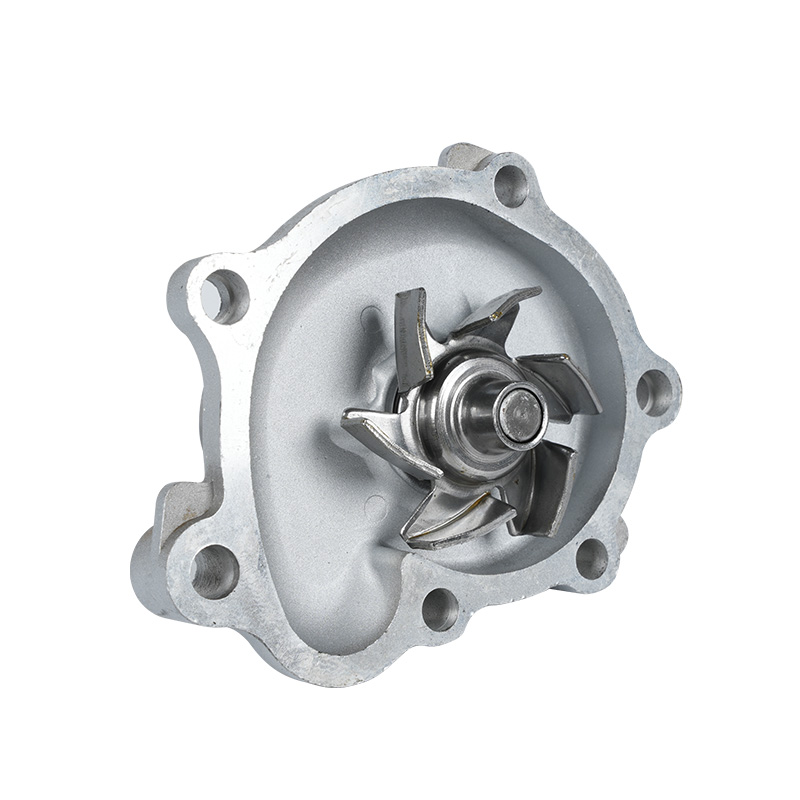

The Yanmar Pump range can be broadly classified into three primary categories based on function and design. The one type is the engine-driven portable water pump, often seen in applications like agricultural irrigation or construction site dewatering. These self-contained units, featuring diesel engines, are valued for their mobility and reliability in off-grid locations. The second category encompasses core hydraulic system components, specifically high-pressure axial piston pumps and gear pumps. These Yanmar Pump units are integral to the operation of excavators, loaders, and other heavy equipment, converting mechanical power into the hydraulic force needed to operate booms and buckets. The third major classification is marine-specific pumps, which include seawater cooling pumps for engines and critical high-pressure fuel injection pumps for marine diesel propulsion systems. Each category addresses distinct technical challenges and operating environments.

Where Are These Pumps Applied?

The application scope of Yanmar Pump technology is extensive. On land, diesel-powered portable pumps are deployed for emergency flood control, with certain models capable of moving over 300 cubic meters of water per hour, providing rapid response capabilities. In the construction and mining industries, the reliable hydraulic pumps within machinery enable continuous operation in demanding conditions, directly impacting project timelines and productivity. The marine applications are equally vital, where seawater pumps ensure engine cooling for vessels ranging from small fishing boats to larger commercial craft, while precision fuel injection pumps are crucial for the efficient and reliable operation of main propulsion engines, directly influencing fuel economy and operational range.

What Is the Role of Remanufacturing?

A significant and growing aspect of the Yanmar Pump ecosystem is the focus on sustainability and lifecycle value through remanufacturing programs. For high-value core components like fuel injection pumps and certain hydraulic pumps, authorized remanufacturing processes offer a cost-effective alternative to purchasing new units. These programs involve the complete disassembly, cleaning, inspection, and replacement of all wear parts with genuine components. The remanufactured Yanmar Pump unit is then reassembled and tested to meet original performance specifications. This process can extend the service life of critical components by a significant margin, often at a fraction of the cost of a new unit, while also reducing waste and environmental impact. It represents a strategic approach to equipment management, emphasizing total cost of ownership and resource efficiency.

The evolution of Yanmar Pump technology is intertwined with broader industry trends. The integration of electronic controls for greater precision in hydraulic and fuel systems, along with a continued emphasis on improving energy efficiency across all pump categories, are key development areas. Furthermore, the expansion of certified remanufacturing and service networks supports the long-term viability of equipment in the field. As global infrastructure demands persist and the focus on sustainable practices intensifies, the role of reliable, efficient, and serviceable pumping solutions from providers like Yanmar Pump remains fundamentally important to a wide array of industries.

For versatile and reliable fluid handling, we recommend the CXL-Y-005 model from ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD. This pump is designed for consistent performance in applications such as water circulation, supply systems, and general industrial transfer tasks. It features a robust construction aimed at durability and longevity, coupled with an energy-efficient design to support lower operational costs. The CXL-Y-005 is engineered for ease of maintenance and stable operation, making it a solid choice for users seeking a dependable and cost-effective solution in commercial or light industrial settings.

English

English 中文简体

中文简体