Kubota Pump Drives Global Water Management Solutions

In the global landscape of industrial and infrastructure development, reliable fluid transfer technology remains a critical enabler. Among the key players providing this essential capability is Kubota Pump, a segment known for its engineering-driven approach to water and wastewater management. With operations spanning numerous continents and a product philosophy centered on durability and efficiency, Kubota Pump technologies are integrated into vital systems that support municipal services, industrial processes, and agricultural productivity worldwide.

What Are the Key Components and Principal Characteristics?

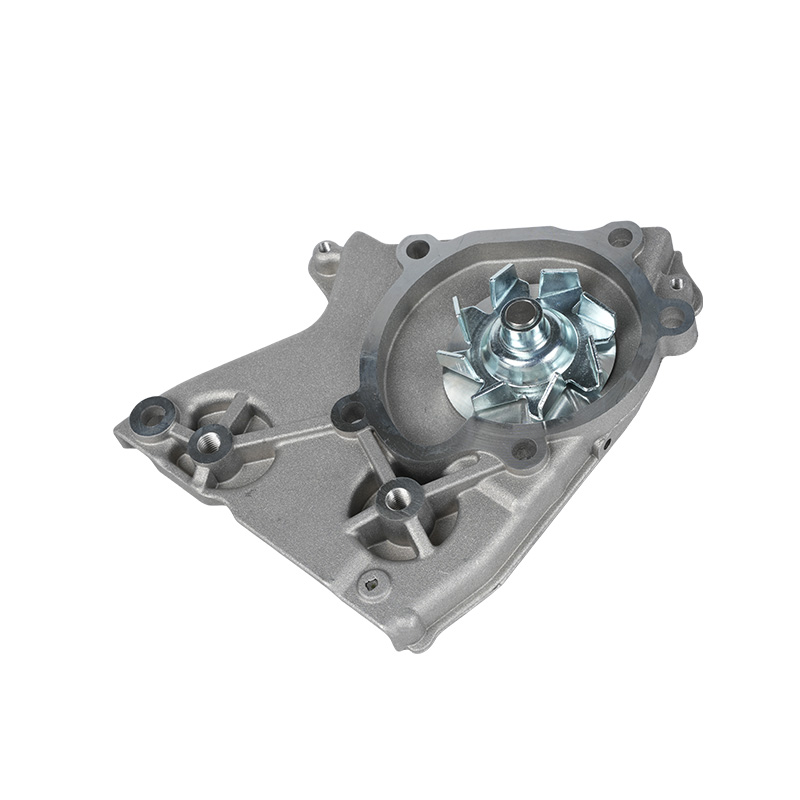

The robustness of a Kubota Pump begins with its core components. The pump casings and impellers are typically manufactured from high-grade cast iron or specialized stainless steels, selected to withstand corrosive fluids and abrasive particles commonly found in raw water and sewage. The heart of the system is a precisely engineered mechanical seal assembly, designed to prevent leakage and ensure long-term submersion integrity, a critical factor for many Kubota Pump installations. These pumps are often characterized by their modular design, which facilitates easier maintenance and parts replacement on-site, aiming to reduce operational downtime. For larger, engine-driven pump sets, the integration with robust diesel power units provides a self-contained solution for remote or temporary applications where grid power is unavailable.

Where Are the Primary Product Application Fields?

The application reach of Kubota Pump products is extensive, addressing needs across the water cycle. In municipal water supply, these pumps are employed in intake stations to draw raw water from rivers or reservoirs, and in booster stations to maintain pressure across distribution networks. Wastewater treatment represents another major field, where Kubota Pump units handle everything from raw sewage lifting at treatment plant inlets to the circulation of activated sludge. Industrial applications are diverse, including process water transfer in manufacturing and cooling water circulation in power generation facilities. Furthermore, in regions facing water scarcity, Kubota Pump technology is applied in large-scale irrigation projects and in critical desalination processes, where high-pressure pumps are essential for reverse osmosis systems.

What Are the Technical Features and Advantages?

The technical philosophy behind Kubota Pump emphasizes performance longevity and operational efficiency. Advanced hydraulic design, often refined through computational fluid dynamics (CFD) analysis, aims to optimize flow patterns and less energy loss. This focus on hydraulic efficiency can translate to measurable reductions in power consumption for end-users. The pumps are also engineered for stability, with designs that seek to control vibration and reduce wear on bearings and shafts. Ease of maintenance is a stated advantage, with features designed to allow for inspection and replacement of seals or wear parts without requiring complete disassembly of the pump unit. This design consideration supports a lower total cost of ownership over the equipment's service life, which can extend for decades in well-maintained systems.

The trajectory for Kubota Pump technology is likely influenced by global trends toward digitalization and sustainability. The integration of smart sensors for condition monitoring and the development of even more energy-efficient models are areas of ongoing focus. As infrastructure demands grow and the need for efficient water management intensifies, the role of reliable, engineered pumping solutions like those offered by the Kubota Pump division is poised to remain significant, underpinning essential services in communities and industries around the world.

For industrial applications requiring efficient, reliable fluid transfer, we recommend the CXL-K-007 pump from ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD. This model is engineered to deliver stable performance and durability in demanding environments, making it suitable for a range of uses including water supply, circulation systems, and light industrial processes. With a focus on robust construction and energy-efficient operation, the CXL-K-007 is designed to less maintenance needs while ensuring consistent flow and pressure. It represents a practical and dependable choice for projects where operational reliability and cost-effectiveness are key priorities.

English

English 中文简体

中文简体