Yanma Pump: Evolving for Efficiency and Versatility

Across agricultural fields, construction sites, and emergency response units worldwide, the distinctive hum of a Yanma pump is a sound synonymous with dependable, portable water transfer. These robust diesel-powered pumps have carved a significant niche in industries where access to grid power is limited and operational reliability is paramount. The enduring relevance of the Yanma pump is rooted in its engineered core, versatile application scope, and its ongoing adaptation to meet modern demands for efficiency and lower environmental impact, securing its position as a fundamental tool in mobile fluid management.

What Defines the Core of a Yanma Pump?

The fundamental strength of a Yanma pump lies in its integrated design, combining a purpose-built air-cooled diesel engine with a high-efficiency centrifugal pump unit. This self-contained powertrain is the defining feature, eliminating dependence on electrical infrastructure and enabling deployment in the many remote locations. Constructed with durability in mind, key components such as the pump casing and impeller are often made from cast iron or engineered composites, providing resistance to abrasion from silt and debris commonly found in agricultural and construction runoff. This focus on ruggedness translates to extended service intervals, with many models designed to operate for over 1,000 hours before requiring major maintenance, a key metric for users in continuous-deployment scenarios like prolonged dewatering.

Where Are Yanma Pumps Primarily Applied?

The application landscape for the Yanma pump is vast, directly supporting critical economic and safety activities. In agriculture, these pumps are indispensable for irrigation and field drainage. Farmers rely on their portability to move water across uneven terrain, with popular models capable of delivering flow rates between 500 and 1,800 liters per minute, directly impacting crop yield and water management efficiency. On construction sites globally, Yanma pump units are standard equipment for dewatering excavations and foundations, keeping projects on schedule. Furthermore, their quick-start capability and high head pressure make them a first-choice tool for firefighting and flood control units in municipal services, where they can be tasked with moving large volumes of water to protect infrastructure and communities during emergencies.

How Is the Yanma Pump Evolving for the Future?

The evolution of the Yanma pump is being shaped by stronger environmental regulations and a global push for sustainable practices. A clear trend is the advancement in engine technology to meet stricter international emission standards, such as the EU Stage V regulations, which necessitate cleaner combustion and often incorporate advanced exhaust treatment. Concurrently, there is a growing integration of digital monitoring features. Modern Yanma pump models are increasingly equipped with sensors that track vital parameters like fuel consumption, engine temperature, and pump pressure. This data, accessible through simple interfaces, facilitates predictive maintenance, helps optimize fuel efficiency—potentially reducing consumption by an estimated 8-15%—and prevents costly downtime by alerting operators to potential issues before they cause failure. This shift towards smarter, cleaner, and more efficient operation ensures the Yanma pump continues to meet the evolving needs of its diverse user base.

The Yanma pump has successfully transitioned from a purely mechanical workhorse to a more refined piece of job-site equipment. Its continued development, balancing proven mechanical reliability with incremental technological upgrades for better fuel economy and connectivity, suggests it will remain a vital asset for professionals who require guaranteed performance in challenging and off-grid environments for the foreseeable future.

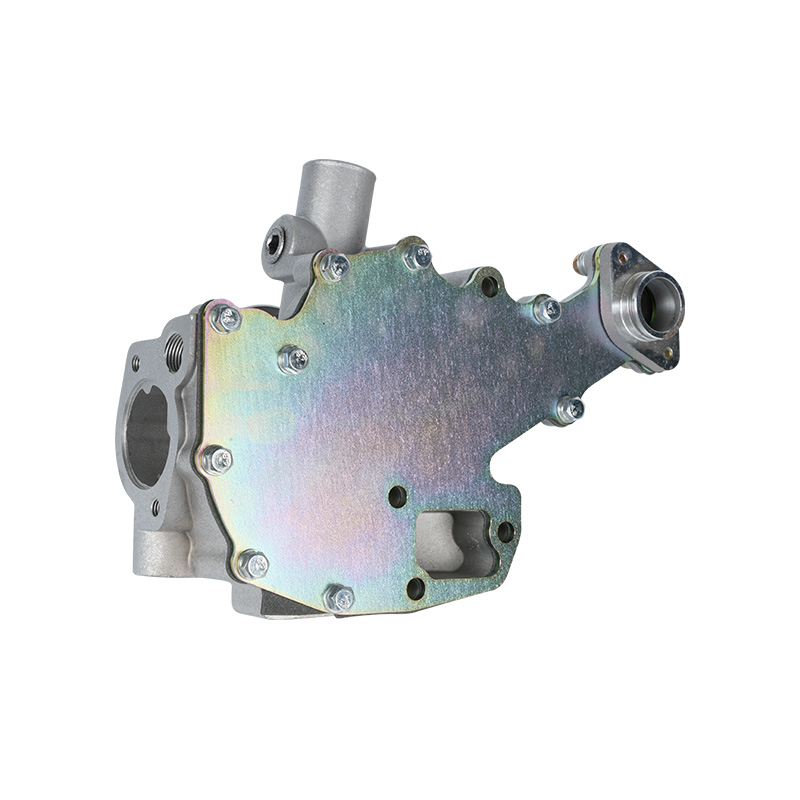

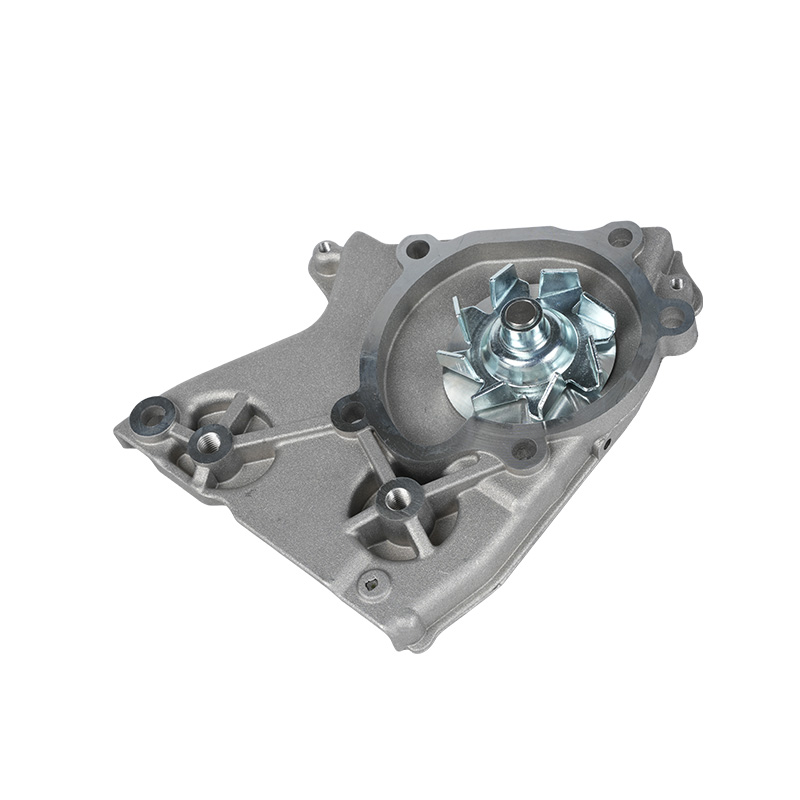

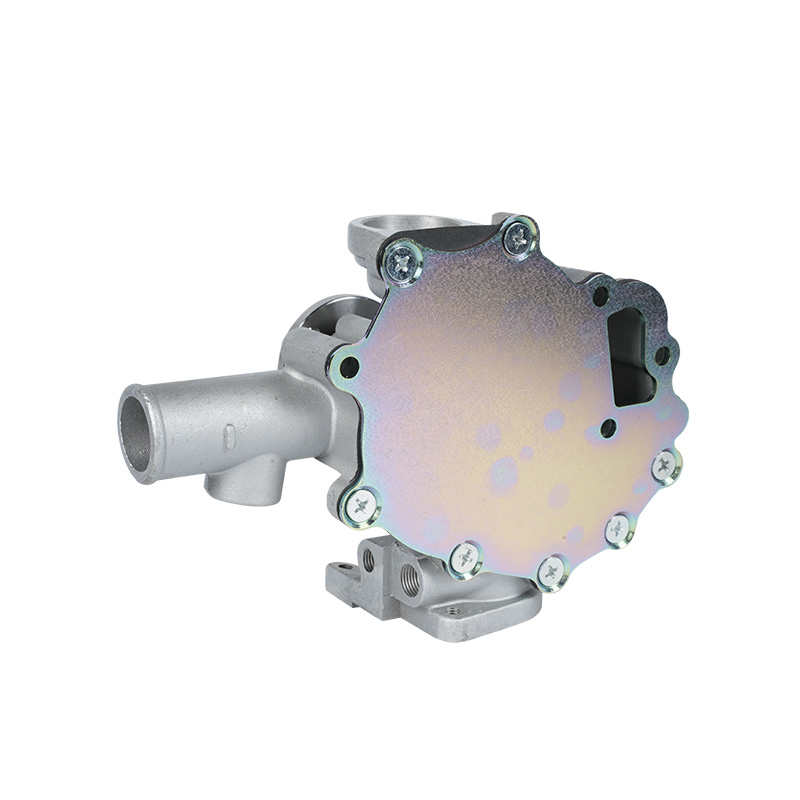

The CXL-Y-003 is a precision-engineered water pump model within the Yanma Pump Series from ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD. The primary purpose of the CXL-Y-003 is to provide reliable and efficient cooling for engines in demanding applications. It is engineered to meet the rigorous performance standards of industrial machinery. As a key component, this pump facilitates the circulation of coolant, playing an essential role in maintaining ideal engine temperature and ensuring long-term operational stability for equipment used in sectors such as construction, agriculture, and industrial manufacturing.

English

English 中文简体

中文简体