Kubota Pump Technology Addresses Diverse Fluid Handling Needs

The term Kubota pump encompasses a broad and strategically important range of products within global industrial and agricultural sectors. Kubota pump expertise spans from the production of specialized large-scale pump equipment to the compact diesel engines that power a wide array of auxiliary pump systems. This diversified approach positions the Kubota pump as a key component in critical applications from municipal waterworks to portable job site equipment, supported by a reputation for engineering reliability and a widespread service network.

What Pump Equipment Does Kubota Manufacture?

Kubota manufactures a dedicated line of industrial pump equipment, primarily engineered for large-scale water handling. A flagship product is the vertical mixed-flow pump, a design optimized for high-volume, low-to-medium head applications. These robust Kubota pumps are commonly deployed in municipal water intake and distribution, as well as in agricultural irrigation and drainage projects. For instance, pump models within this series can handle impressive flow capacities, with some units designed to manage volumes exceeding 2500 cubic meters per minute. Furthermore, Kubota provides engineered solutions for demanding processes like seawater desalination, supplying high-pressure pump systems that are integral to reverse osmosis plants in regions facing water scarcity.

Which Pumps Are Driven by Kubota Engines?

Beyond its proprietary pump hardware, the Kubota pump ecosystem importantly includes a vast array of third-party pump sets powered by Kubota's industrial diesel engines. This application is particularly prominent in the firefighting and construction sectors. Portable diesel-driven firefighting units, for example, frequently utilize compact Kubota diesel engines ranging from 25 to over 100 horsepower. These engines drive high-pressure centrifugal pumps capable of delivering water at rates of 500 gallons per minute or more, providing essential mobile water supply. Similarly, in construction and mine dewatering, trailer-mounted "trash pumps" powered by Kubota engines are a common sight, built to handle solids-laden water and keep work sites dry.

What Are Coolant Pumps for Kubota Engines?

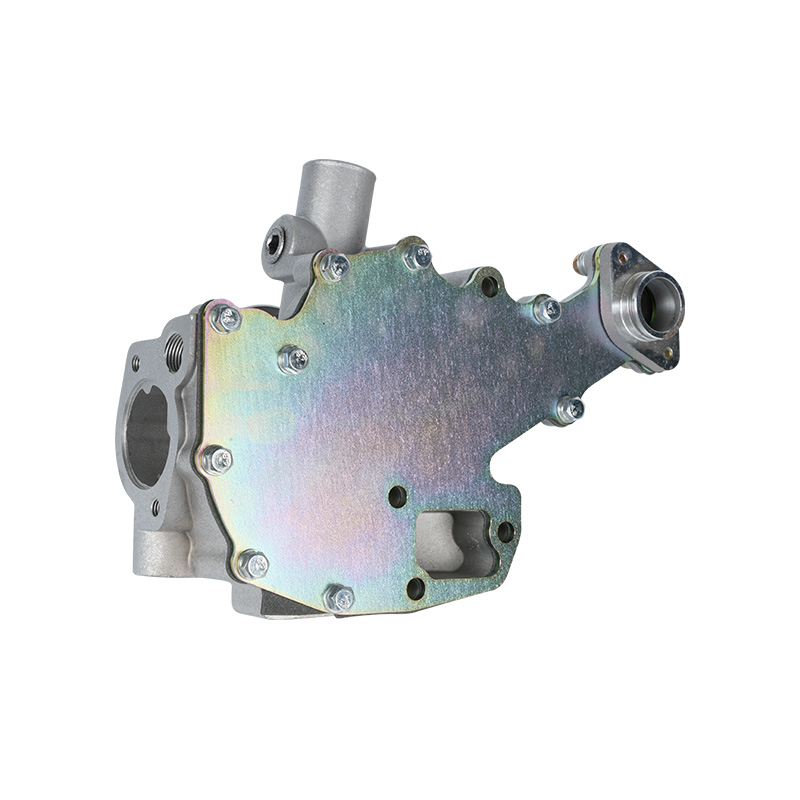

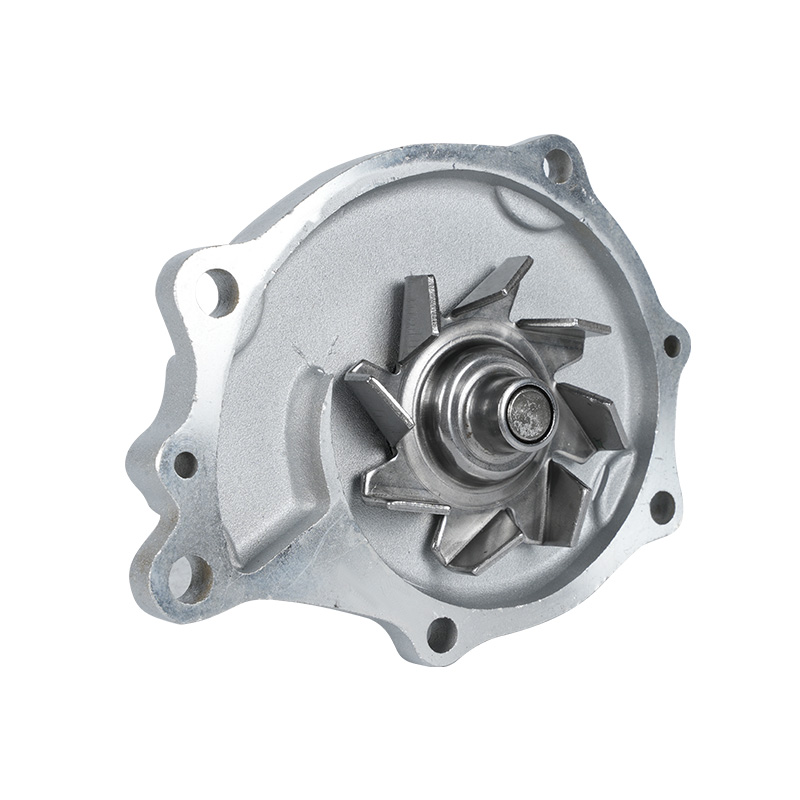

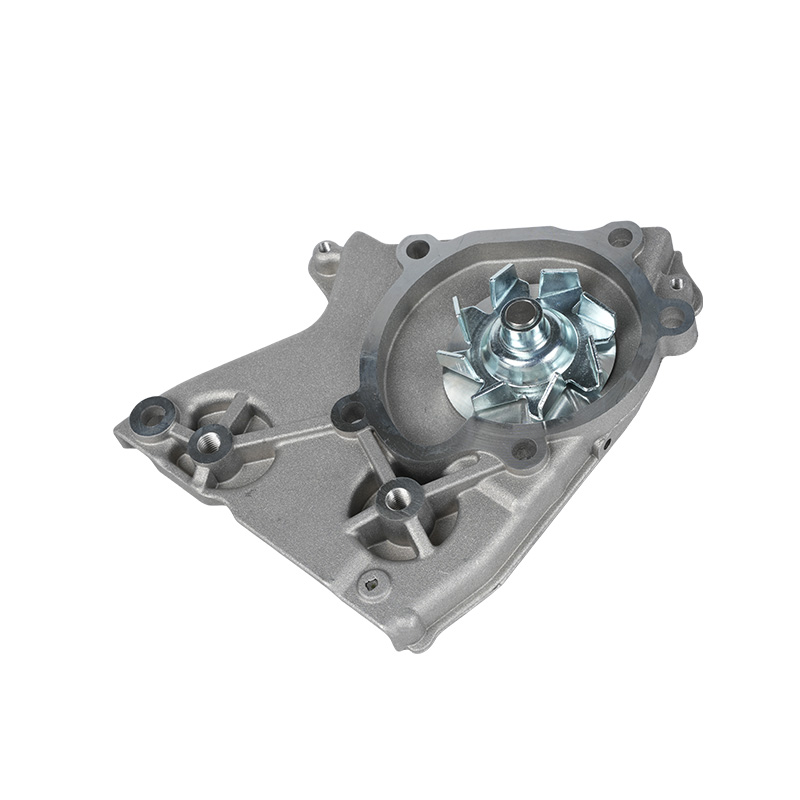

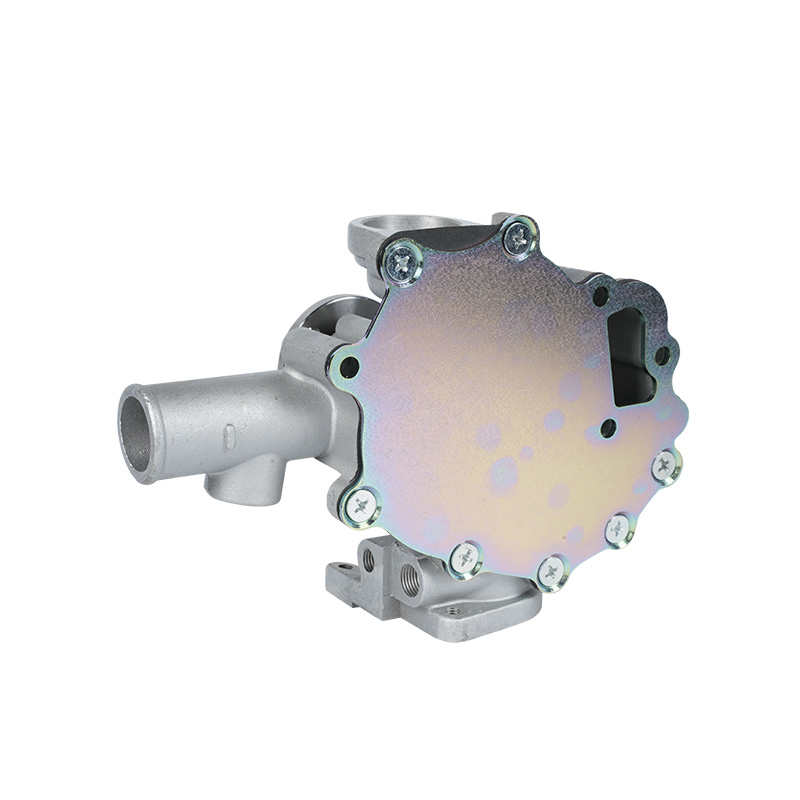

The Kubota pump definition also extends to a critical internal component: the coolant pump within Kubota's own diesel engines. This centrifugal pump is an essential part of the engine's cooling system, circulating coolant to maintain ideal operating temperature and prevent overheating. As a wear item, the Kubota coolant pump is a frequently sought-after replacement part in the aftermarket. These pumps are model-specific, designed to fit a wide range of Kubota powerplants, from small 3-cylinder engines used in compact machinery to larger V3800 series engines found in industrial generators and agricultural equipment. The reliable function of this internal Kubota pump is fundamental to the longevity and performance of the hundreds of thousands of Kubota engines operating worldwide.

The continued relevance of the Kubota pump across these distinct categories highlights the company's integrated approach to fluid and power system solutions. From major infrastructure projects utilizing its large-scale pump equipment to the reliability demanded from its engines in auxiliary pump applications, the Kubota pump remains a trusted element in global industry. Ongoing development in pump efficiency and engine emissions technology ensures that Kubota pump products are adapting to meet evolving environmental standards and performance expectations across diverse markets.

The CXL-K-005, from the specialized KUBOTA Pump Series by ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD., is a precision-engineered coolant pump designed as a direct-fit, OEM-quality replacement. Its primary function is to ensure efficient coolant circulation within the engine's closed-loop system, which is critical for maintaining ideal operating temperature, preventing overheating, and ensuring long-term engine reliability for the specific machinery it serves.

English

English 中文简体

中文简体