The Function and Importance of Cylinder Water Pumps

Water pumps are essential components in many industrial, agricultural, and residential applications, and cylinder water pumps are a specific type designed to provide efficient and reliable water transfer. These pumps are engineered to move water through a system by utilizing the principles of fluid mechanics and mechanical engineering.

Cylinder water pumps are designed to transfer water from one location to another. They operate by creating a vacuum or pressure differential within a cylinder, which draws water in and then pushes it out through a discharge outlet. The movement of water is typically powered by a mechanical force, such as an electric motor or an internal combustion engine, which drives a piston or plunger within the cylinder.

The primary function of a cylinder water pump is to provide a continuous flow of water at a desired pressure and volume. This is achieved through the reciprocating motion of the piston, which creates suction on the intake side and pressure on the discharge side. The efficiency of this process depends on several factors, including the design of the pump, the condition of its components, and the specific application for which it is used.

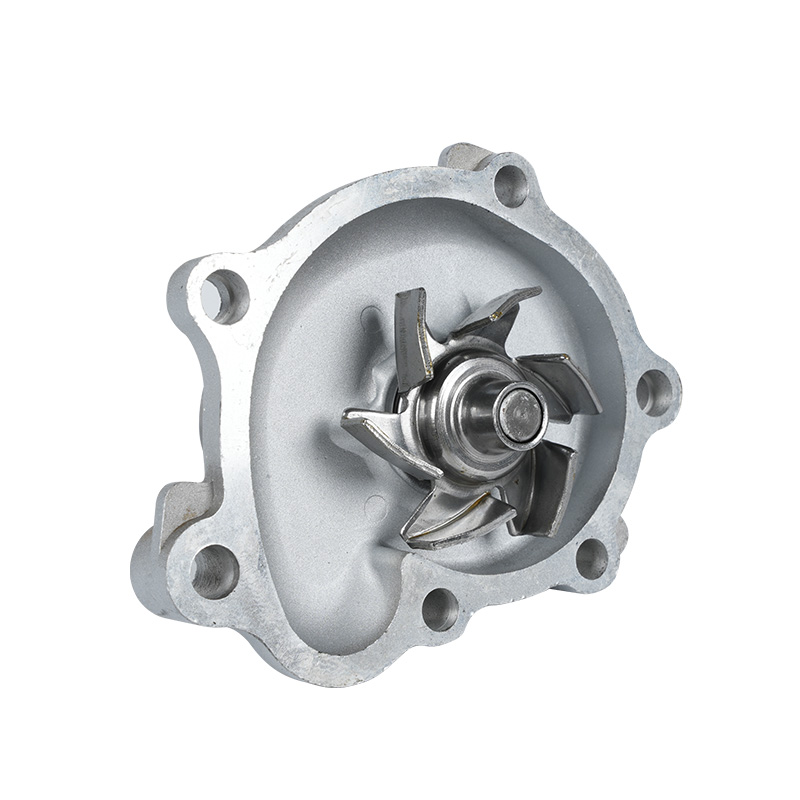

Cylinder water pumps consist of several key components, including the cylinder, piston, valves, and drive mechanism. The cylinder houses the piston, which moves up and down to create the necessary pressure and vacuum. Intake and discharge valves control the flow of water into and out of the cylinder, ensuring that water moves in the correct direction. The drive mechanism, typically powered by an electric motor or engine, provides the mechanical force needed to move the piston.

Cylinder water pumps are versatile and can be used in a wide range of applications. In residential settings, they are often used for irrigation systems, transferring water from wells or storage tanks to gardens and fields. In industrial applications, cylinder water pumps are used for cooling systems, water treatment plants, and transferring water in manufacturing processes. Their ability to handle high pressures and volumes makes them suitable for tasks that require a consistent and reliable water supply.

Proper maintenance is crucial for the longevity and efficiency of cylinder water pumps. Regular inspection and servicing can help identify potential issues before they pilot costly repairs or downtime. Key maintenance tasks include checking fluid levels, inspecting for leaks, and replacing worn components such as seals and valves.

One of the more critical aspects of maintaining a cylinder water pump is ensuring that the water being pumped is free from debris and contaminants. Dirty water can cause wear on the pump's components, pilot reduced efficiency and potential damage. Regularly cleaning or replacing filters can help prevent these issues and extend the life of the pump.

Despite regular maintenance, cylinder water pumps may still encounter issues that can affect their performance. Common problems include reduced flow rates, unusual noises, and leaks. These issues can be caused by a variety of factors, such as worn components, clogged filters, or contaminated water.

Reduced flow rates may indicate a problem with the pump's internal components, such as worn valves or a damaged piston. Unusual noises, such as knocking or grinding, can suggest issues with the pump's drive mechanism or bearings. Leaks can be caused by damaged seals or hoses and should be addressed promptly to prevent further damage and water loss.

Cylinder water pumps are essential tools for transferring water in a variety of applications. Their efficient design and reliable performance make them a popular choice for both residential and industrial use.

English

English 中文简体

中文简体