The Critical Role of Forklift Water Pumps

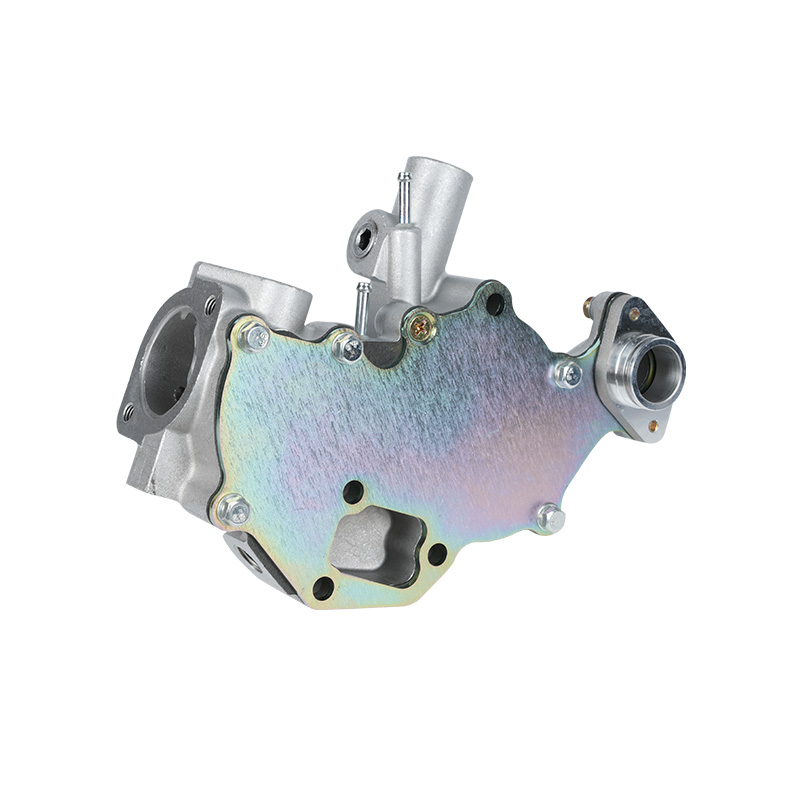

The forklift water pump has become an essential component in modern material handling equipment, playing a crucial role in maintaining ideal engine temperatures and ensuring reliable performance. Recent advancements in design and materials have improved the efficiency and durability of these specialized pumps, making them more effective in demanding industrial environments.

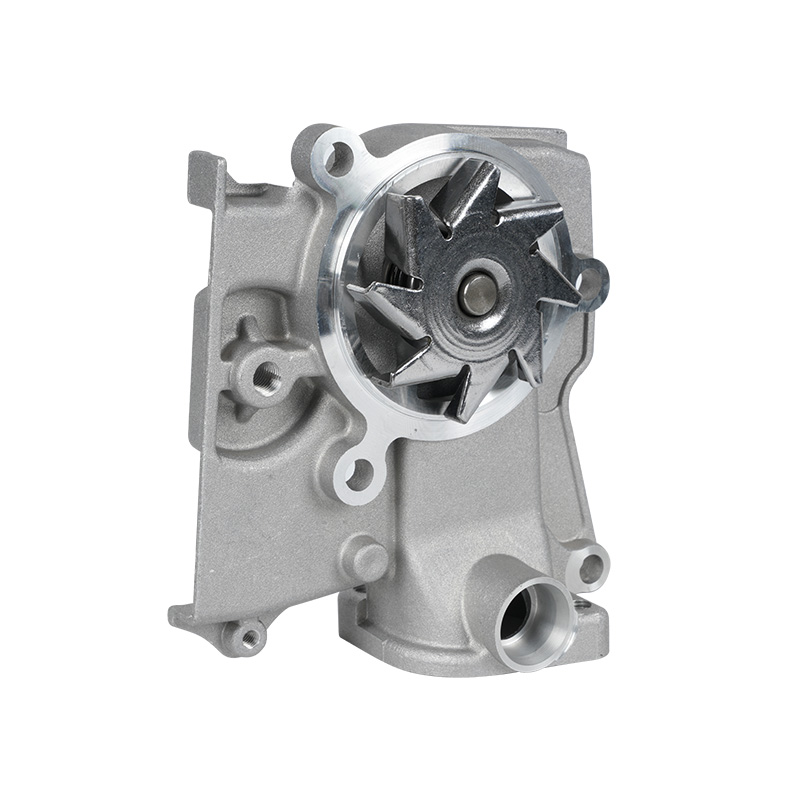

Forklift water pumps are specifically engineered to circulate coolant through the engine system, preventing overheating during extended operation. Unlike standard automotive water pumps, these components are built to withstand the unique stresses of material handling equipment, including frequent starts and stops, heavy loads, and prolonged use in challenging conditions. The latest generation of forklift water pumps features enhanced impeller designs that improve coolant flow while reducing energy consumption, contributing to better overall equipment efficiency.

One of the key developments in forklift water pump technology is the use of advanced materials that resist corrosion and wear. Many modern pumps now incorporate stainless steel components and composite materials that can handle various coolant types while maintaining long-term reliability. This is particularly important in environments where forklifts may be exposed to moisture, chemicals, or bad temperatures that could accelerate component degradation.

The industrial sector has seen significant benefits from improved forklift water pump designs. Warehouse operators and logistics companies report fewer instances of equipment downtime since adopting these upgraded cooling system components. Maintenance teams appreciate the extended service intervals offered by current forklift water pump models, which translate to lower operational costs and improved equipment availability. Some newer designs also feature simplified installation processes, reducing the time required for replacements or repairs.

Another notable trend is the integration of smart monitoring capabilities in forklift water pump systems. While not yet universal, some advanced models now include sensors that can track pump performance and coolant flow rates. This data helps maintenance personnel identify potential issues before they cause equipment failure, supporting a more proactive approach to fleet management. Such technological improvements align with the broader movement toward connected industrial equipment and predictive maintenance strategies.

Manufacturers have also focused on making forklift water pumps more adaptable to different equipment configurations. Many models now offer multiple mounting options and connection types to accommodate various forklift makes and models. This flexibility simplifies the parts inventory process for operations managing mixed equipment fleets, as fewer specialized pump variants need to be stocked.

Environmental considerations have influenced recent forklift water pump developments as well. Energy-efficient designs help reduce the overall power consumption of material handling equipment, while improved sealing technologies less the risk of coolant leaks that could create environmental hazards. These features are increasingly important as industries seek to meet sustainability goals and comply with stricter environmental regulations.

The importance of proper cooling system maintenance, with the forklift water pump at its core, cannot be overstated for operations relying on material handling equipment. As technology progresses, these components will likely become even more integrated with overall equipment monitoring systems, providing operators with greater visibility into their fleet's health and performance. This ongoing development ensures that the humble forklift water pump will continue to be a key factor in industrial productivity for years to come.

English

English 中文简体

中文简体