Forklift Water Pump is Becoming Known to People

The Forklift Water Pump represents a critical component in industrial material handling operations, serving as the heart of the engine cooling system in numerous forklift models. This vital equipment ensures proper thermal management for forklift engines during demanding operational cycles. Understanding the technical specifications and maintenance requirements of the Forklift Water Pump becomes essential for operations managers and maintenance professionals seeking to optimize equipment reliability and operational efficiency.

How does a forklift water pump work?

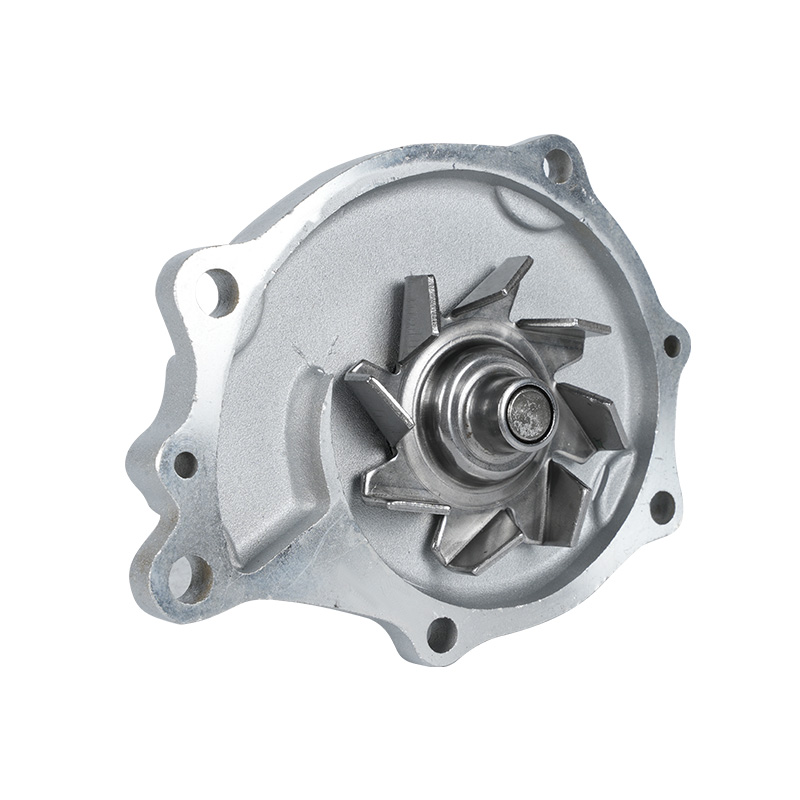

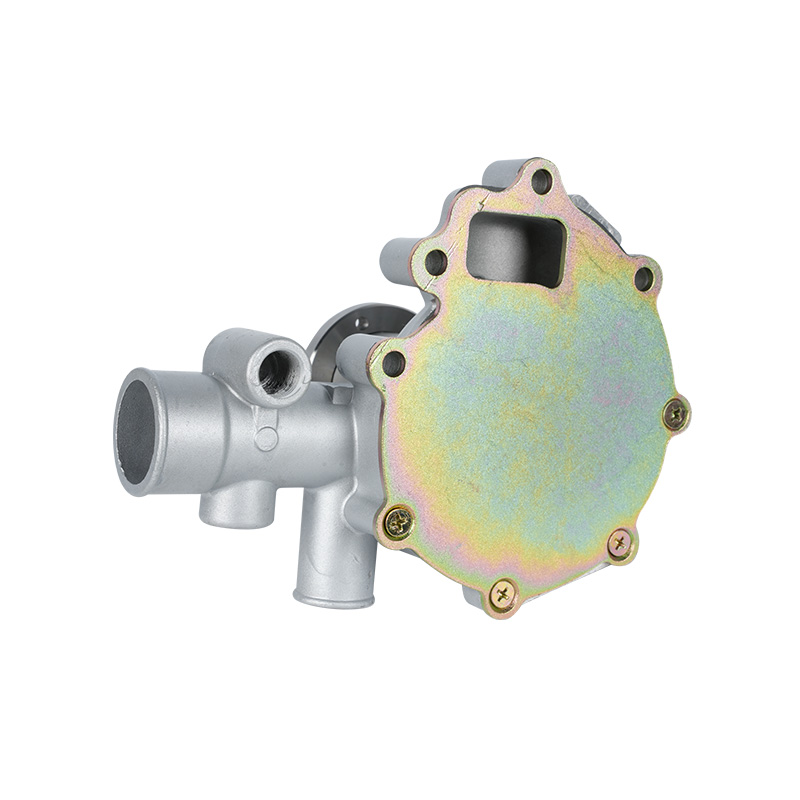

The operational principle of the Forklift Water Pump centers on its function as a centrifugal pumping mechanism driven directly by the engine's rotational force. This crucial component typically circulates approximately 60 to 100 liters of coolant per minute through the engine block and radiator system, maintaining ideal operating temperatures between 85°C and 95°C. The Forklift Water Pump achieves this circulation through impeller rotation at speeds ranging from 2000 to 6000 RPM, depending on engine specifications and operational demands. This continuous movement of coolant prevents localized hot spots and ensures heat distribution remains within design parameters. The efficient operation of the Forklift Water Pump directly influences fuel consumption metrics, with properly functioning units contributing to maintenance of ideal combustion conditions. The design of the Forklift Water Pump incorporates precision-engineered seals that withstand system pressures up to 15 PSI while preventing coolant leakage into bearing assemblies.

What are the main advantages of a forklift water pump?

The properly specified Forklift Water Pump delivers significant operational benefits that extend beyond basic temperature regulation. Equipment utilizing correctly matched Forklift Water Pump components typically demonstrates engine temperature consistency within 5°C of ideal range, directly supporting combustion efficiency. The thermal management provided by the Forklift Water Pump contributes to documented engine lifespan extensions of 30-40% compared to systems with compromised cooling performance. Operations data indicates that appropriate Forklift Water Pump selection reduces overheating-related downtime by approximately 25% in high-utilization environments. These performance advantages position the Forklift Water Pump as a crucial investment for maintaining operational continuity and small unexpected maintenance interventions.

What are the key considerations for maintaining a forklift water pump?

Several maintenance practices significantly influence the service life and reliability of the Forklift Water Pump. Regular inspection intervals between 250-500 operational hours allow for early identification of potential issues before they escalate into major failures. Coolant quality maintenance represents another crucial factor, with recommended replacement cycles between 2000-4000 hours depending on environmental conditions and coolant specifications. Systematic maintenance of the Forklift Water Pump includes verification of drive belt tension every 500 operational hours, with adjustment when deflection exceeds 10-15 millimeters under standard testing pressure. These maintenance protocols contribute directly to achieving typical Forklift Water Pump service intervals of 8000-10000 operational hours in standard applications.

The comprehensive understanding of Forklift Water Pump operation, advantages, and maintenance requirements provides valuable guidance for selection decisions in diverse operational contexts. The technical specifications and performance data associated with the Forklift Water Pump serve as essential reference points for maintenance planning and operational budgeting. Through appropriate selection and systematic maintenance of the Forklift Water Pump, operations can achieve significant improvements in equipment reliability and total operating costs. The continued development of Forklift Water Pump technology focuses on enhancing material durability and operational efficiency to meet evolving demands in material handling applications across various industries.

Product Recommendations

Recommend CZL-F-058 from ZHEJIANG JINRUI PUMP INDUSTRY CO., LTD.

English

English 中文简体

中文简体