Forklift Hydraulic Pumps: Powering Efficiency in Material Handling

In the dynamic world of material handling, forklifts are indispensable tools that facilitate the movement of heavy loads with precision and efficiency. Central to the operation of forklifts is the forklift hydraulic pump, a critical component that enables the lifting and lowering of loads. These pumps are designed to provide reliable and consistent performance, ensuring that forklifts can operate smoothly in various industrial settings.

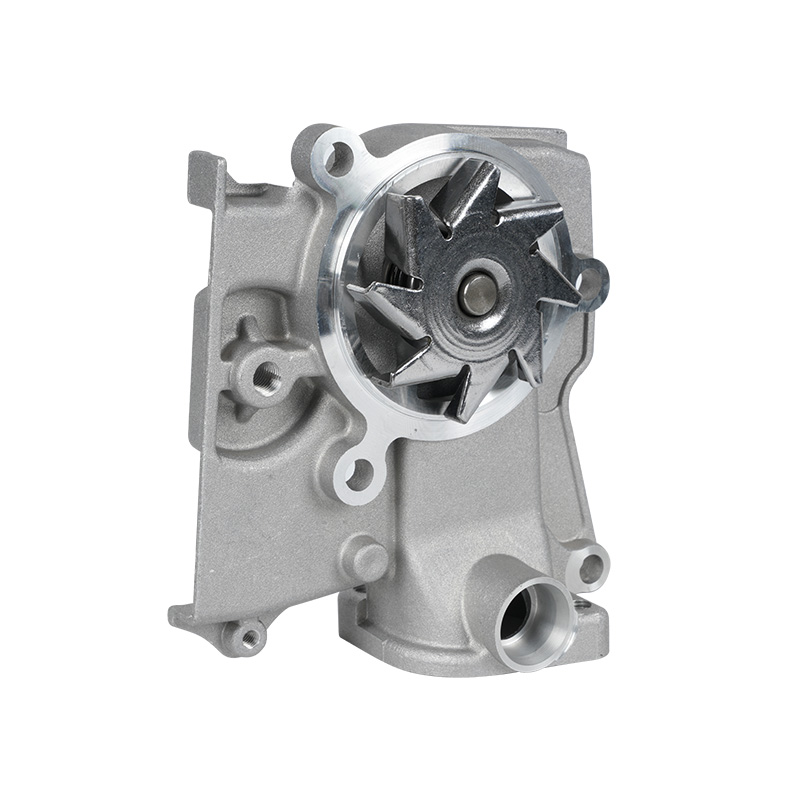

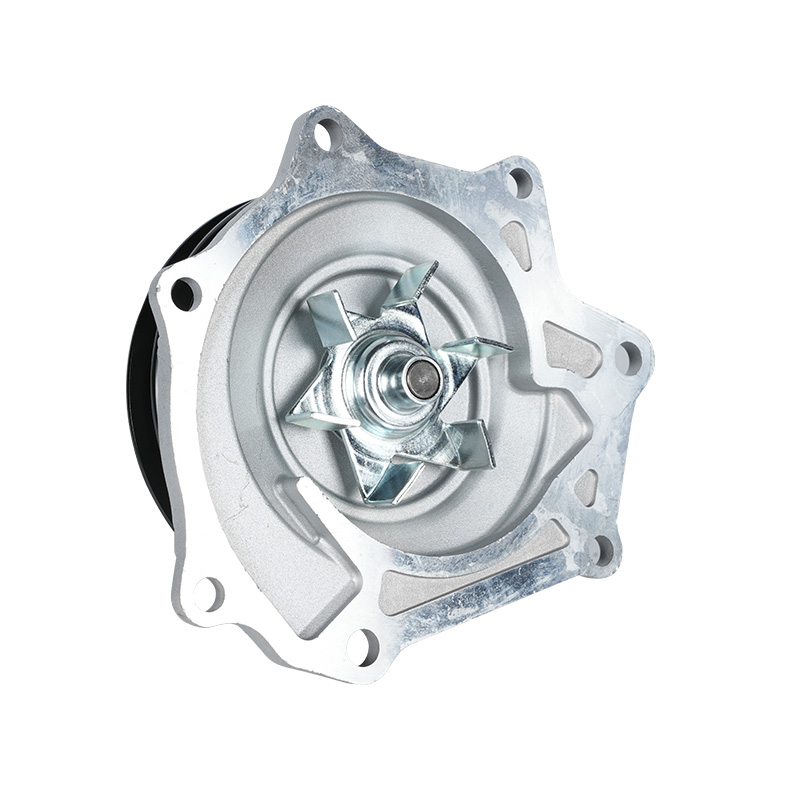

Forklift hydraulic pumps are engineered to deliver the necessary power to lift heavy loads to significant heights. They work by converting mechanical energy from the forklift’s engine into hydraulic pressure, which is then used to drive the lifting mechanism. This hydraulic system allows forklifts to handle a wide range of load capacities, making them versatile tools in warehouses, construction sites, and manufacturing facilities.

One of the key advantages of forklift hydraulic pumps is their durability. These pumps are built to withstand the rigorous demands of daily use in industrial environments. They are designed to operate efficiently even under heavy loads and challenging conditions, ensuring that forklifts can continue to function without frequent breakdowns. This reliability is crucial in maintaining the efficiency of material handling operations.

Maintenance is an essential aspect of ensuring the longevity and performance of forklift hydraulic pumps. Regular inspections and servicing can help identify potential issues before they cause significant problems. Tasks such as checking fluid levels, inspecting hoses for wear, and ensuring proper lubrication are vital in maintaining the pump’s efficiency. Many forklift manufacturers provide detailed maintenance guidelines to help operators keep their hydraulic pumps in ideal condition.

Energy efficiency is another important consideration in the design of forklift hydraulic pumps. Modern pumps are engineered to operate efficiently, reducing energy consumption and lowering operational costs. This not only helps to less the environmental impact of forklift operations but also provides cost savings for businesses. By optimizing the hydraulic system, forklifts can achieve better fuel efficiency and reduced wear on components.

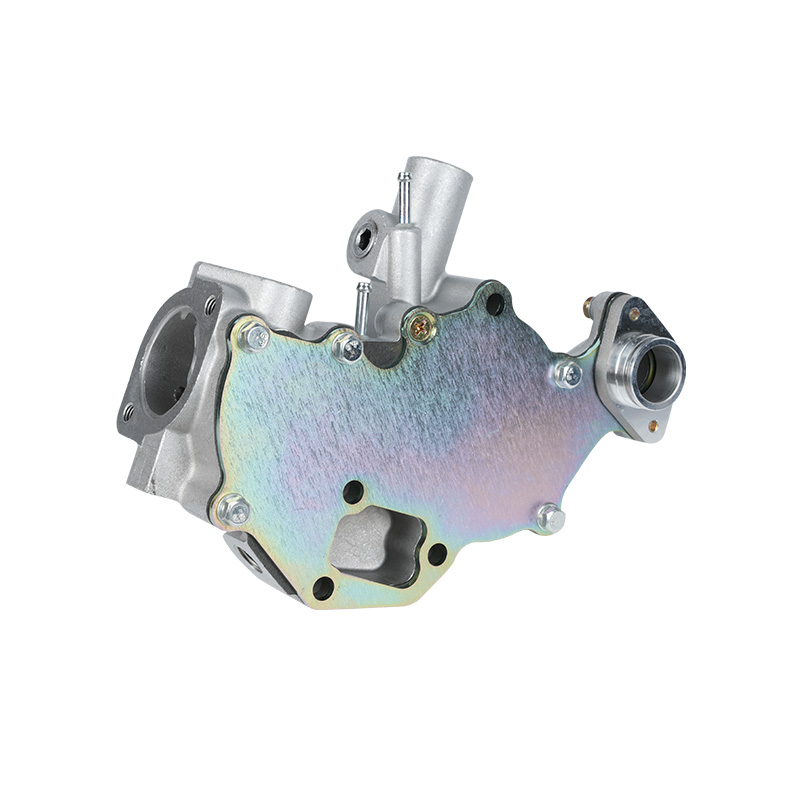

In addition to their practical benefits, forklift hydraulic pumps are available in various configurations to suit different types of forklifts and applications. Whether it’s for a small warehouse forklift or a heavy-duty industrial lift, there is a hydraulic pump designed to meet the specific requirements of the equipment. This versatility ensures that forklifts can be tailored to the needs of different industries and tasks.

As the demand for efficient material handling solutions continues to grow, forklift hydraulic pumps are playing a crucial role in enhancing the performance of forklifts. Their ability to provide reliable power, withstand heavy use, and operate efficiently makes them an essential component in modern forklift design. With ongoing advancements in hydraulic technology, these pumps are set to become even more efficient and durable, further improving the capabilities of forklifts in various industrial applications.

Forklift hydraulic pumps are vital components that enable the efficient operation of forklifts in material handling. Their durability, energy efficiency, and adaptability make them a reliable choice for businesses looking to optimize their material handling processes. As technology continues to advance, forklift hydraulic pumps will remain at the forefront of innovation, ensuring that forklifts continue to deliver exceptional performance in demanding industrial environments.

English

English 中文简体

中文简体